Stainless steel is a versatile material comprised of a steel alloy and a small percentage of chromium—the addition of chromium adds to the material’s corrosion resistance, a trait that earned stainless steel its name. Because stainless steel is also low-maintenance, oxidation resistant, and doesn’t affect other metals it comes in contact with, it is frequently used in a large array of applications, especially in piping and tubing manufacturing.

Stainless steel pipe is primarily used in piping systems for the transport of fluids or gases. Stainless steel pipe resists oxidation, making it a low-maintenance solution that is suitable for high temperature and chemical applications. Because it is easily cleaned and sanitized, stainless steel pipe is also desired for applications involving food, beverages and pharmaceutical applications.

Welded stainless steel pipe

Standards: ASTM A312

Grades: 304/L and 316/L

Sizes: 1/4" Thru 36"

Schedules: 10s, 20, 40s, 80s

Seamless Stainless Steel Pipe

Standards: ASTM A312

Grades: 304/L and 316/L

Sizes: 1/4" Thru 20”

Schedules: 10s, 40s, 80s, 160, and XXH

True 40, True 80

Equipment:

Application of Stainless Steel Tube

- Kitchen benches, sinks, troughs, equipment and appliances

- Architectural paneling, railings & trim

- Chemical containers, including for transport

- Heat Exchangers

- Woven or welded screens for mining, quarrying & water filtration

- Threaded fasteners

- Water Supply Systems

- Power Plant

- Paper and pulp Industry

- General Purpose Applications

- Fabrication Industry

- Food Processing Industry

- Industrial Structural Project

- Oil and Gas Pipeline

- Chemical Industry

- Plumbing Industrial

Our Advantages:

1. China-leading product service provider and exporter of steel pipe

2. Competitive price and quality from our own factory

3. One-stop Resource Integration

4. Passed the ISO9001, CE, SGS certification every year

5. Best service with 24-hour response

6. Flexible payment methods

7. Strong production capacity

8. Fast delivery and standard export packaging

9. OEM/ODM

|

NB |

Size |

OD mm |

40S mm |

5S mm |

10S mm |

S 10 mm |

S 20 mm |

S 40 mm |

S 60 mm |

XS/80S mm |

S 80 mm |

S 100 mm |

S 120 mm |

S 140 mm |

S 160 mm |

XXS mm |

|

1/8” |

10.29 |

1.24 |

1.73 |

2.41 |

||||||||||||

|

1/4” |

13.72 |

1.65 |

2.24 |

3.02 |

||||||||||||

|

3/8” |

17.15 |

1.65 |

2.31 |

3.20 |

||||||||||||

|

15 |

1/2” |

21.34 |

2.77 |

1.65 |

2.11 |

2.77 |

3.73 |

3.73 |

4.78 |

7.47 |

||||||

|

20 |

3/4” |

26.67 |

2.87 |

1.65 |

2.11 |

2.87 |

3.91 |

3.91 |

5.56 |

7.82 |

||||||

|

25 |

1” |

33.40 |

3.38 |

1.65 |

2.77 |

3.38 |

4.55 |

4.55 |

6.35 |

9.09 |

||||||

|

32 |

1 1/4” |

42.16 |

3.56 |

1.65 |

2.77 |

3.56 |

4.85 |

4.85 |

6.35 |

9.70 |

||||||

|

40 |

1 1/2” |

48.26 |

3.68 |

1.65 |

2.77 |

3.68 |

5.08 |

5.08 |

7.14 |

10.15 |

||||||

|

50 |

2” |

60.33 |

3.91 |

1.65 |

2.77 |

3.91 |

5.54 |

5.54 |

9.74 |

11.07 |

||||||

|

65 |

2 1/2” |

73.03 |

5.16 |

2.11 |

3.05 |

5.16 |

7.01 |

7.01 |

9.53 |

14.02 |

||||||

|

80 |

3” |

88.90 |

5.49 |

2.11 |

3.05 |

5.49 |

7.62 |

7.62 |

11.13 |

15.24 |

||||||

|

90 |

3 1/2” |

101.60 |

5.74 |

2.11 |

3.05 |

5.74 |

8.08 |

8.08 |

||||||||

|

100 |

4” |

114.30 |

6.02 |

2.11 |

3.05 |

6.02 |

8.56 |

8.56 |

11.12 |

13.49 |

17.12 |

|||||

|

125 |

5” |

141.30 |

6.55 |

2.77 |

3.40 |

6.55 |

9.53 |

9.53 |

12.70 |

15.88 |

19.05 |

|||||

|

150 |

6” |

168.27 |

7.11 |

2.77 |

3.40 |

7.11 |

10.97 |

10.97 |

14.27 |

18.26 |

21.95 |

|||||

|

200 |

8” |

219.08 |

8.18 |

2.77 |

3.76 |

6.35 |

8.18 |

10.31 |

12.70 |

12.70 |

15.09 |

19.26 |

20.62 |

23.01 |

22.23 |

|

|

250 |

10” |

273.05 |

9.27 |

3.40 |

4.19 |

6.35 |

9.27 |

12.70 |

12.70 |

15.09 |

19.26 |

21.44 |

25.40 |

28.58 |

25.40 |

|

|

300 |

12” |

323.85 |

9.53 |

3.96 |

4.57 |

6.35 |

10.31 |

14.27 |

12.70 |

17.48 |

21.44 |

25.40 |

28.58 |

33.32 |

25.40 |

|

|

350 |

14” |

355.60 |

9.53 |

3.96 |

4.78 |

6.35 |

7.92 |

11.13 |

15.09 |

12.70 |

19.05 |

23.83 |

27.79 |

31.75 |

35.71 |

|

|

400 |

16” |

406.40 |

9.53 |

4.19 |

4.78 |

6.35 |

7.92 |

12.70 |

16.66 |

12.70 |

21.44 |

26.19 |

30.96 |

36.53 |

40.49 |

|

|

450 |

18” |

457.20 |

9.53 |

4.19 |

4.78 |

6.35 |

7.92 |

14.27 |

19.05 |

12.70 |

23.83 |

29.36 |

34.93 |

39.67 |

45.24 |

|

|

500 |

20” |

508.00 |

9.53 |

4.78 |

5.54 |

6.35 |

9.53 |

15.09 |

20.62 |

12.70 |

26.19 |

32.54 |

38.10 |

44.45 |

50.01 |

|

|

550 |

22” |

558.80 |

9.53 |

4.78 |

5.54 |

6.35 |

9.53 |

22.23 |

12.70 |

28.58 |

34.93 |

41.28 |

47.63 |

53.98 |

||

|

600 |

24” |

609.60 |

9.53 |

5.54 |

6.35 |

6.35 |

9.53 |

17.48 |

24.61 |

12.70 |

30.96 |

38.89 |

46.02 |

52.37 |

59.54 |

|

|

650 |

26” |

660.40 |

9.53 |

7.92 |

12.70 |

12.70 |

||||||||||

|

700 |

28” |

711.20 |

9.53 |

7.92 |

12.70 |

12.70 |

||||||||||

|

750 |

30” |

762.00 |

9.53 |

6.35 |

7.92 |

7.92 |

12.70 |

12.70 |

||||||||

|

800 |

32” |

812.80 |

9.53 |

7.92 |

12.70 |

17.48 |

12.70 |

|||||||||

|

850 |

34” |

863.60 |

9.53 |

7.92 |

12.70 |

17.48 |

12.70 |

|||||||||

|

900 |

36” |

914.40 |

9.53 |

7.92 |

12.70 |

19.05 |

12.70 |

Chemical Composition

| Grades | C max | Mn max | P max | S max | Si max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Mechanical Properties

| Grades | Itemper | Tensile Psi | Yield Psi | Elong % | Rockwell Hardness |

| 304 | Annealed | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Annealed I1/8 Hard |

80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Annealed | 85000 min | 35000 min | 50 min | 80 min |

| Annealed | 80000 min | 30000 min | 50 min | 75 min |

Painting & Coating :Annealed, Pickling, Polished

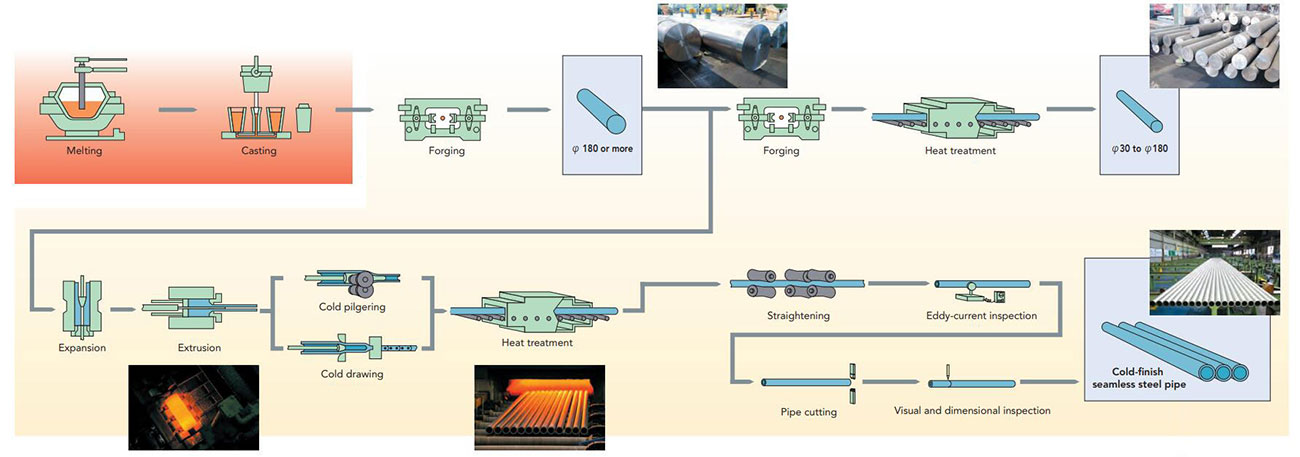

Manufacturing process of Seamless Steel Pipe