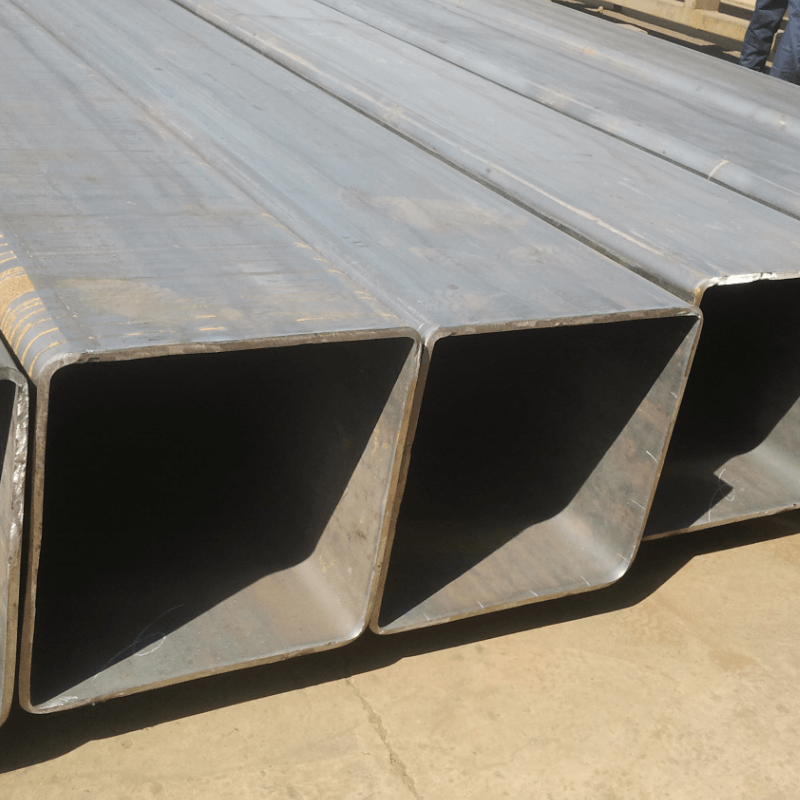

Hollow structural section (HSS) is a type of metal profile with a hollow cross section. The term is used predominantly in the United States, or other countries which follow US construction or engineering terminology.

HSS members can be circular, square, or rectangular sections, although other shapes such as elliptical are also available. HSS is only composed of structural steel per code.

HSS is sometimes mistakenly referenced as hollow structural steel. Rectangular and square HSS are also commonly called tube steel or box section. Circular HSS are sometimes mistakenly called steel pipe, although true steel pipe is actually dimension and classed differently from HSS. (HSS dimensions are based on exterior dimensions of the profile; pipes are also manufactured to an exterior tolerance, albeit to a different standard.) The corners of HSS are heavily rounded, having a radius which is approximately twice the wall thickness. The wall thickness is uniform around the section.

In the UK, or other countries which follow British construction or engineering terminology, the term HSS is not used. Rather, the three basic shapes are referenced as CHS, SHS, and RHS, being circular, square, and rectangular hollow sections. Typically, these designations will also relate to metric sizes, thus the dimensions and tolerances differ slightly from HSS.

Features of H-Beam Steel

H metal beam steel is known for being incredibly strong.

An H-beam can be built up, which means it may be built up to any size or height, making it an ideal material for construction.

Types Of H-Beam

There are many product specifications of H-beams, and the classification methods are as follows.

(1) According to the flange width of the product, it is divided into wide flange, medium flange and narrow flange H-beams. The flange width B of wide flange and medium flange H-beam is greater than or equal to the web height H. The flange width B of narrow flange H-beam is approximately equal to one-half of the web height H. The flange width of narrow flange H-beam is approximately equal to the web height H.

(2) According to the product use, it is divided into H-beam, H-beam column, H-beam pile, and very thick flange H-beam. Sometimes parallel-legged channels and parallel-flange T-beams are also included in the range of H-beams. Generally, narrow flange H-beam is used as beam material, and wide flange H-beam is used as column material, according to which there are beam H-beam and column H-beam.

(3) According to the production method, it is divided into welded H-beam and rolled H-beam.

(4) According to the size specification, it is divided into large, medium and small size H-beams. Usually, the products with web height H above 700mm are called large, 300-700mm are called medium, and those less than 300mm are called small. By the end of 1990, the world's largest H-beam web height of 1200mm and flange width of 530mm.

Difference Between Steel I-Beam and H-Beam

What Is H-Beam?

H beam is a structural beam made of rolled steel. It is incredibly strong. It gets its name because it looks like a capital H over the cross-section.

What Is I-Beam?

An I-beam has an I-shaped form. Two horizontal planes, referred to as flanges, are joined by a vertical element, known as the weft, to form an I-beam.

The term "I-beam" comes from the fact that it resembles a capital letter when viewed through a cross-section and has tapering edges. An I-beam has a cross-section that is taller than it is wide at the flange.

Which Is Stronger H Beam or I-Beam?

H-beam: H-beam often has a thicker central web, making it stronger.

I-beam: Since I-beam frequently has a narrower central web than H-beam, it frequently cannot withstand as much stress.

What Is H Beam Used For?

H Beams are frequently used in the construction of bridges, large trailers, and buildings, among other things. H beams are able to support heavier weights than I beams due to their slightly different cross-section shape, thicker central web, and broader flanges.

What Is the Purpose of an I Beam?

Because of its excellent utility, I beams are the preferred form for structural steel construction. I beams are ideal for unidirectional bending parallel to the web because of their form. The web resists shear stress, but the horizontal flanges resist bending movement.

H-Beam and I-Beam: Applications

H beams are perfect for mezzanines, platforms, bridges, and other typical residential and commercial buildings since they have thicker walls and flanges.

In residential constructions, broad flanges are frequently employed. H-beams are the chosen material for the framework of the trailer and vehicle since their interior dimensions are consistent.

For structural steel buildings, bridges, and other civil structures, I-beams are the favored shape choice due to their increased resistance to flanges.

They are also utilized to build the framework and support columns for trains, elevators, beds for trailers and vehicles, winches, and residential and commercial building projects.

Square tubes sizes

| Size (mm) | Wall Thickness (mm) | Size (mm) | Wall Thickness (mm) |

| 20*20 | 1.2 | 70*7060*80100*40 | 1.8 |

| 1.3 | 2 | ||

| 1.4-1.5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2.5-4.0 | ||

| 2 | 4.5-5.0 | ||

| 2.2 | 5.5-5.75 | ||

| 2.3 | 75*7560*90100*50 | 1.8 | |

| 2.5-2.75 | 2 | ||

| 25*2520*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1.5 | 2.5-4.0 | ||

| 1.7 | 4.5-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | 80*80100*60100*80120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2.5-3.0 | 2.3 | ||

| 30*3030*4025*4020*40 | 1 | 2.5-4.0 | |

| 1.2 | 4.5-5.0 | ||

| 1.3 | 5.5-5.75 | ||

| 1.5 | 7.5-7.75 | ||

| 1.7 | 100*100120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2.5-5.0 | ||

| 2.3 | 5.5-5.75 | ||

| 2.5*2.75 | 7.5-7.75 | ||

| 3 | 120*120140*80150*100160*80 | 2.5 | |

| 40*4030*5025*50 | 1.2 | 2.75 | |

| 1.3 | 3 | ||

| 1.4-1.5 | 3.25-5.0 | ||

| 1.7 | 5.5-7.0 | ||

| 1.8 | 7.5-7.75 | ||

| 2 | 140*140150*150200*100 | 3.5-4.0 | |

| 2.2-2.3 | 4.5-5.0 | ||

| 2.5-4.0 | 5.25-7.0 | ||

| 50*5060*4030*6040*50 | 1.5 | 7.5-7.75 | |

| 1.7 | 160*160180*180 | 3 | |

| 1.8 | 3.5 | ||

| 2 | 3.75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 5.25-5.75 | ||

| 2.5*-4.0 | 7.5-7.75 | ||

| 4.25-5.0 | 60*6040*8075*7550*7050*80 | 2.3 | |

| 60*6040*8075*4550*7050*80 | 1.5 | 2.5-4.0 | |

| 1.7 | 4.25-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

Rectangular Pipe sizes

| Size (mm) | Wall Thickness (mm) | Size (mm) | Wall Thickness (mm) |

| 20*20 | 1.2 | 70*7060*80100*40 | 1.8 |

| 1.3 | 2 | ||

| 1.4-1.5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2.5-4.0 | ||

| 2 | 4.5-5.0 | ||

| 2.2 | 5.5-5.75 | ||

| 2.3 | 75*7560*90100*50 | 1.8 | |

| 2.5-2.75 | 2 | ||

| 25*2520*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1.5 | 2.5-4.0 | ||

| 1.7 | 4.5-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | 80*80100*60100*80120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2.5-3.0 | 2.3 | ||

| 30*3030*4025*4020*40 | 1 | 2.5-4.0 | |

| 1.2 | 4.5-5.0 | ||

| 1.3 | 5.5-5.75 | ||

| 1.5 | 7.5-7.75 | ||

| 1.7 | 100*100120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2.5-5.0 | ||

| 2.3 | 5.5-5.75 | ||

| 2.5*2.75 | 7.5-7.75 | ||

| 3 | 120*120140*80150*100160*80 | 2.5 | |

| 40*4030*5025*50 | 1.2 | 2.75 | |

| 1.3 | 3 | ||

| 1.4-1.5 | 3.25-5.0 | ||

| 1.7 | 5.5-7.0 | ||

| 1.8 | 7.5-7.75 | ||

| 2 | 140*140150*150200*100 | 3.5-4.0 | |

| 2.2-2.3 | 4.5-5.0 | ||

| 2.5-4.0 | 5.25-7.0 | ||

| 50*5060*4030*6040*50 | 1.5 | 7.5-7.75 | |

| 1.7 | 160*160180*180 | 3 | |

| 1.8 | 3.5 | ||

| 2 | 3.75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 5.25-5.75 | ||

| 2.5*-4.0 | 7.5-7.75 | ||

| 4.25-5.0 | 60*6040*8075*7550*7050*80 | 2.3 | |

| 60*6040*8075*4550*7050*80 | 1.5 | 2.5-4.0 | |

| 1.7 | 4.25-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

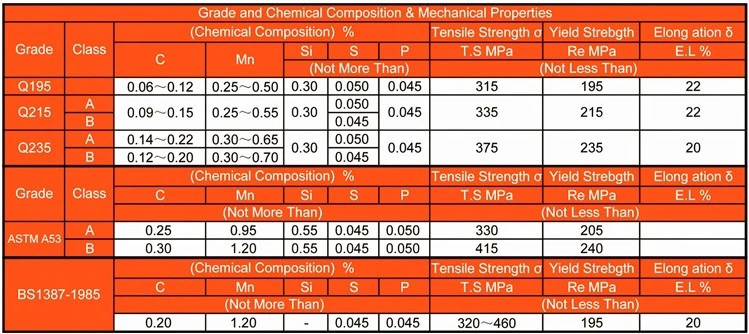

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

EN 10210 Hot finished structural hollow sections of non-alloy and fine grain structural steels

EN 10219 Cold formed welded structural hollow sections of non-alloy and fine grain steels

ASTM A53 used as structural steel or for low-pressure plumbing

Bare, Black Painting,Lightly Oiled

Painted Structural Steel Tube

Painted SHS (square hollow sections) and RHS (rectangular hollow sections) are high-strength cold-formed hollow steel sections that are primer painted for protection during storage and handling.

Hollow Structural Sections (HSS) are lengths of high-strength welded steel tubing which is used for structural elements in buildings, general structures, and a variety of manufactured products.