Coated steel pipe means the pipe that is by the processing after the corrosion, which can effectively prevent or slow the steel pipe occurs in the course of transport and chemical or electrochemical reaction corrosion phenomena. Coated steel pipe can effectively prevent or slow down the corrosion of steel pipes to extend service life and reduce operating costs pipe.

Applications of coated steel pipe

coated steel pipe base metal is including spiral, straight seam pipe, seamless steel pipe, etc., which are widely used in pipeline projects in the field of petroleum, chemical, natural gas, heating, sewage treatment, water, bridges, steel structures, piling and other marine water.

Standard:

DIN 30670: Polyethylene coatings of steel pipes adn fittings.

DIN 30678: Polythylene coatiing of steel pipes and fittings.

SY/T0413-2002: Technical standard of polythelene coating for buried steel pipeline.

Types of anti-corrosion coating

Pipe corrosion types are divided into external corrosion and internal corrosion.

1. FBE anticorrosive epoxy powder

FBE epoxy powder preservative structure: electrostatic spraying

epoxy powder coating on the pipe surface, a film. The coating

has a coating operation is simple, clean, good impact resistance

and flexural properties of the coating, temperature resistance

advantages.

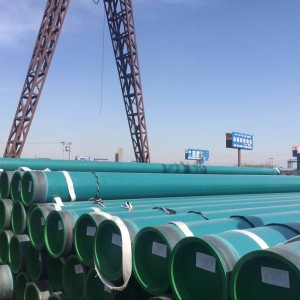

2. 2PE/3PE corrosion

2PE/3PE corrosion structure: the steel surface electrostatic spraying

epoxy powder and binder twine lateral lateral wound polyethylene

coating, combined with three excellent performance, thereby significantly

improving the overall quality of corrosion of the pipe. Resistant to chemical

corrosion, cathodic stripping, resistance to mechanical damage performance.

3. Coal tar epoxy

Coal tar epoxy structure: epoxy resin + filler made of coal tar pitch

anticorrosive coating on the steel surface coated glass fabric as reinforcement

corrosion layer formation, commonly used in the pipe wall corrosion. thickness of 0.5 ~ 1.0mm.

3PE Steel Pipe Sizes

| Coating Type | Coating Layer | Coating Thickness |

| Three layers polyethylene | Inside layer: epoxy (Green) | 2.0-4.5mm |

| Mid layer: adhensive (White) | ||

| Outsidelayer:polyethylene (Black) | ||

| Two layers polyethylene | Inside layer: adhensive | 2.0-4.5mm |

| Outside layer: polythene | ||

| Epoxy | Epoxy | 200-400um |

| Two layers epoxy | Inside layer: expoxy (Green) | 400-800um |

| Outside layer:intensity epoxy (sage green) | ||

| Three layers polyethylene | Inside layer: expoxy (Green) | 2.5-3mm |

DIN30670 for three-layer extruded and one- or multi-layered sintered polyethylene-based coatings

DIN30671 thermoset plastic coating For buried steel pipes

DIN30678 polypropylene coatings for steel pipes

CAN/CSA Z245.20/-Z245.21-02 external fusion bond epoxy coating for steel pipe/external polyethylene coating for pipe

SY/T4013-2002 for transport water, gas, oil,piling coating

SY/T0315-97 PE coating for buried steel pipe

One Layer / Double Layer FBE anti-corrosive coating powder (200um~800um)

3PP (Polypropylene) Coated Steel Pipe

DIN30678 standard technical specification for polypropylene coating for steel pipe and pipe fittings

3PP Coating Advantages:

The 3PP coated steel pipe refers to steel tubing with three layers of PP(Polypropylene) coating. It offers high electric strength, acid resistance, alkali resistance, salt-tolerance, electric insulation, long service life, thermal endurance and impact resistance. Because of advanced steel pipe coating technology, this type of plastic coated steel pipe features well-bonded coatings.

3PP Coating Applications:

The 3PP coating steel pipe is suitable for transferring special materials, such as high temperature materials, because it offers high electric strength, acid resistance, alkali resistance, salt-tolerance, electric insulation, long service life, thermal endurance and is impact resistant.

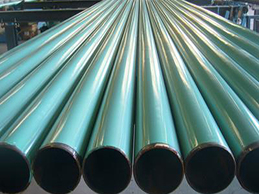

FBE Coated Steel Pipe

FBE coating pipe is Fusion Bonded Epoxy coating steel pipe. It is an externally applied heat resin for pipe. With a form of dry powder at thickness 300-600 microns on to the heated surface of pipe. Once the FBE coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the pipe surface. The FBE layer in a even form and have good resistance to the chemical reaction.

Polyurethane Insulation Coating Steel Pipe

The polyurethane direct buried heat preservation pipe is a direct buried preheating heat preservation pipe with good heat preservation performance, safety and reliability, and low engineering cost. The buried thermal insulation pipe not only has the advanced technology and practical performance that is difficult to compare with the traditional trench and overhead laying pipeline, but also has obvious social and economic benefits, and is also a powerful measure for heating and energy saving.

It is characterized by a multi-purpose use to prevent the spread of fire and good fire safety performance. Black jacket insulation pipe includes spiral steel pipe, straight seam steel pipe and seamless steel pipe. The outer layer is made of black polyethylene and is called a black jacket insulation tube.