Pipe Caps act as protective device and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the the ends of hydraulic or pneumatic pipes and tubes. They are used in the plumbing apparatus of domestic, commercial and industrial water supply lines, machinery and processing equipment etc. They are also fitted on water pump lines with the sole purpose of removing air blocks. Pipe caps are highly demanded as an important category of pipe fittings.Steel Pipe Cap is also called Steel Plug, it usually welded to the pipe end or mounted on the external thread of the pipe end to cover the pipe fittings. To close the pipeline so the function is the same as the pipe plug.

Types of Pipe Caps:

Pipe caps come in many different types and the type vary according to the application. However pipe caps also vary depending on their construction features and it is very important for the buyer to know the right type of pipe cap. Based on construction, pipe caps are of the following types:

Threaded Caps:

These caps are female threaded. The thread can be either straight or tapered, also referred as NPT. Generally, caps have a female thread and plugs have a male thread.

Tapered Caps:

These caps have tapered sides, which offers a close fit. Some of these fittings can be used either as a cap or a plug. Tapered caps and plugs are multi-functional and go well with male and female NPT threads, straight tubes and bars; and male straight threads. These fittings have a tapered body to provide a secure and firm friction fit while facilitating easy removal. The tapered caps are designed to provide protection for all internal and external, threaded and non-threaded fittings against damage, dirt or moisture that can occur.

Anti-Roll Caps:

These caps are round in shape with a slightly square end. This prevents pipes and tubes from rolling.

BW Steel Cap:

BW steel pipe cap is the butt weld type of fittings, connecting methods is to use butt welding. So BW cap ends in beveled or plain.

Socket Weld Steel Pipe Cap

Socket weld cap is to connecting pipes and caps by insert the pipe into the access shoulder area of the socket weld cap.

Pipe Cap Material Grades

| Stainless Steel Pipe Cap | ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Carbon Steel Pipe Cap | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Pipe Cap | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Pipe Cap | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex Pipe Cap | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Nickel Alloy Pipe Cap | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

Standards :ASME / ANSI – B 16.9, ASTM A403 – ASME SA403, ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

Dimension : ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Size : Seamless Reducer ( 1/2″~24″), ERW / Welded / Fabricated Reducer (1/2″~48″)

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Form : Pipe End Caps, Pipe Caps, End Caps.

Types : Seamless / Welded / Fabricated

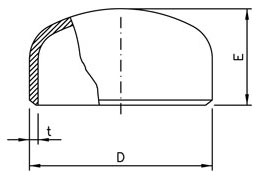

END CAPS DIMENSIONS :

ANSI 16.9 DIMENSIONS BUTTWELD END CAPS

|

inches |

mm |

Height |

|

|

D |

E |

||

|

1/2 |

15 |

21,34 |

25,40 |

|

3/4 |

20 |

26,67 |

31,75 |

|

1″ |

25 |

33,40 |

38,10 |

|

1 1/4 |

32 |

42,16 |

38,10 |

|

1 1/2 |

40 |

48,26 |

38,10 |

|

2 |

50 |

60,32 |

38,10 |

|

2 1/2 |

65 |

73,02 |

38,10 |

|

3 |

80 |

88,90 |

50,80 |

|

3 1/2 |

90 |

101,60 |

63,50 |

|

4 |

100 |

114,30 |

63,50 |

|

5 |

125 |

141,30 |

76,20 |

|

6 |

150 |

168,27 |

88,90 |

|

8 |

200 |

219,07 |

101,60 |

|

10 |

250 |

273,05 |

127,00 |

|

12 |

300 |

323,85 |

152,40 |

|

14 |

350 |

355,60 |

165,10 |

|

16 |

400 |

406,40 |

177,80 |

|

18 |

450 |

457,20 |

203,20 |

|

20 |

500 |

508,00 |

228,60 |

|

22 |

550 |

558,80 |

254,00 |

|

24 |

600 |

609,60 |

266,70 |

|

28 |

700 |

711,20 |

266,70 |

|

Dimension in mm |

|||

ANSI 16.9 TOLERANCES

|

DIMENSIONAL TOLERANCES – CAPS |

||||

|

For all fittings |

Caps |

|||

|

Nominal Pipe Size (NPS) |

Outside Ø at Bevel |

Inside Ø at End |

Wall Thickness |

Overall Length E |

|

1/2 a 2 1/2 |

1 |

0,8 |

Not |

4 |

|

3 a 3 1/2 |

1 |

1,6 |

less |

4 |

|

4 |

+2 -1 |

1,6 |

than |

4 |

|

5 a 6 |

+3 -1 |

1,6 |

87,50% |

7 |

|

8 |

2 |

1,6 |

of nominal |

7 |

|

10 |

+4 -3 |

3,2 |

tickness |

7 |

|

12 a 18 |

+4-3 |

3,2 |

7 |

|

|

20 a 24 |

+6-5 |

4,8 |

7 |

|

|

26 a 30 |

+7 -5 |

4,8 |

10 |

|

|

32 a 48 |

+7 -5 |

4,8 |

10 |

|

BUTT WELD CAPS – WEIGHTS

|

WEIGHTS OF FITTINGS |

||||

|

NPS |

CAPS |

|||

|

Sch. |

Sch. |

Sch. |

Sch. |

|

|

1/2 |

0.04 |

0.04 |

0.05 |

0.05 |

|

3/4 |

0.05 |

0.05 |

0.06 |

0.08 |

|

1 |

0.09 |

0.09 |

0.13 |

0.17 |

|

1 1/4 |

0.11 |

0.11 |

0.15 |

0.18 |

|

1 1/2 |

0.15 |

0.15 |

0.20 |

0.22 |

|

2 |

0.17 |

0.17 |

0.25 |

0.30 |

|

2 1/2 |

0.25 |

0.25 |

0.45 |

0.50 |

|

3 |

0.40 |

0.40 |

0.70 |

0.90 |

|

4 |

0.60 |

0.60 |

1.20 |

1.60 |

|

5 |

1.00 |

1.00 |

1.90 |

2.70 |

|

6 |

1.40 |

1.40 |

2.90 |

4.30 |

|

8 |

2.50 |

2.50 |

5.10 |

7.60 |

|

10 |

3.90 |

3.90 |

9.00 |

12.0 |

|

12 |

6.50 |

6.50 |

13.5 |

17.5 |

|

14 |

8.00 |

8.00 |

16.0 |

20.5 |

|

16 |

14.5 |

14.5 |

20.5 |

26.0 |

|

18 |

17.0 |

17.0 |

26.0 |

34.0 |

|

20 |

18.0 |

18.0 |

32.0 |

43.0 |

|

24 |

26.0 |

26.0 |

46.0 |

60.0 |

|

Approximate weights in kg, density 8 kg/dm3 |

||||

Stainless Steel End Pipe Cap : ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Alloy Steel End Pipe Cap : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex & Super Duplex Steel End Pipe Cap : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Carbon Steel End Pipe Cap : ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Nickel Alloy End Pipe Cap : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ).

Light Oiling, Black Painting

Surface treatment:

Transparent oil, rust-proof black oil or hot galvanized.

Special design available All the production process are made according to ISO9001:2000 strictly.

Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

Depending on their construction, pipe caps contain threaded cap, tapered cap and anti-roll cap etc.

Our products like end cap are packaged to make sure that there’s no damage throughout transit. Just in case of exports, customary export packaging is completed in wooden boxes or cases. All end cap are marked with Trademark (Company’s LOGO), Grade, Size and Lot No. On requests we can do custom marking on our products.