Pipe cross comes into equal cross and reducing cross,and the raw materials of which include a wide range, like carbon steel, alloy steel, stainless steel, low temperature steel, and high performance steel, etc. Our pipe crosses feature high strength, good toughness and resistance to corrosion, and they are widely used in many industries, such as petroleum, power generation, natural gas, chemical, shipbuilding, paper making etc.

Pipe Cross Types

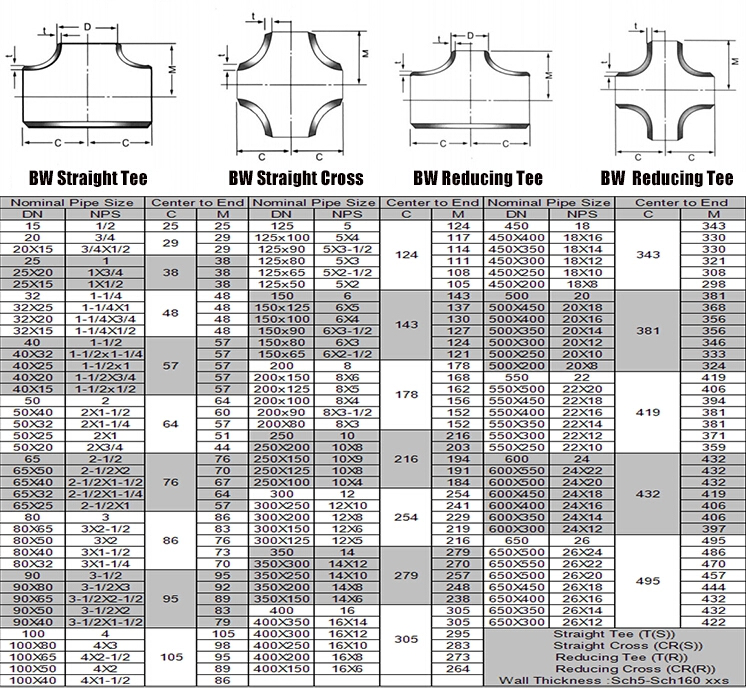

Equal Cross

The equal pipe cross is one type of the pipe cross, just like a equal tee, the equal crosses means all the 4 ends of the cross are in same diameter. The pipe cross, like a road cross, is the joint of 4 pipes. Receiving the pressure from the 4 pipes, the weld joint between the pipes and cross must be very strong.

Reducing cross

The Reducing Cross Pipe Fitting also called as unequal pipe cross, it is the pipe cross which have four branch ends are not in the same diameters.

Outside Diameter: Seamless Cross Fitting ( 1/2″~24″), ERW / Welded / Fabricated Cross Fitting (1/2″~48″)

Type: Seamless, Welded, Equal Cross, Reducing Cross

Wall Thickness: 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Value Added Services: Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering

Production Grades: Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Couple Nickel

Manufacturing Standards

ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43

DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

EN: EN10253-1, EN10253-2

ASTM A403 – ASME SA403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.9 – Factory-Made Wrought Fittings Butt welding

ASME B16.25 – Butt welding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Butt welding Returns

MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

Pipe Cross Material

Stainless Steel Pipe Cross; ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel Pipe Cross: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Pipe Cross: ASTM A420 WPL3, A420 WPL6

Alloy Steel Pipe Cross: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP

Duplex Pipe Cross: ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462

Nickel Alloy Pipe Cross: ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

|

Pattern |

Weld |

Seamless |

|

Nominal size |

1/2”-48” (DN15-DN1200) |

1/2”-20” (DN15-DN500) |

|

Wall thickness |

2~100mm |

2~50mm |

|

Bend radius |

SCH5S-SCH160 ,XXS |

SCH5-SCH160 |

|

Type |

cross/reducing cross |

cross/reducing cross |

Standards: ANSI – B 16.9

ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’

ASME B16.9 – ‘ Wrought Butt welding Fittings”

ASME B16.25 – ‘Butt welding Ends’

ASME B16.28 – ‘Wrought Steel Butt welding Short Radius Elbows and Returns’

API 590-605

MSS SP-43 – ‘Fabricated & Wrought Butt-Welding Fittings for Corrosion Resistant, Low Pressure Applications’

Light Oiling, Black Painting

Normal packing:plastic film or bubble paper wrapped on product’s surface ,protect ends with caps,pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .