A steel pipe reducer is a component used in the pipelines to reduce its size from large to small bore in accordance to the inner diameter. The length of the reduction here is equal to an average of the smaller and larger pipe diameters. Here, the reducer can be used as a nozzle. The reducer helps in meeting the existing piping of varied sizes or hydraulic flow of the piping systems.

1. Pipe Reducer Material Types

Carbon Steel Reducer vs Stainless Steel Reducer

The reducers can be made of Carbon Steel, Alloy, or Stainless steel and much more. In comparison to the Stainless Steel Reducer, Carbon Steel Reducer possesses high-pressure resistance, higher strength, and wear resistant but this can be easily corroded.

Carbon Steel Reducer material standards and grades:

A234 WPB, A420 WPL6, MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 and 70.

For Stainless Steel Reducer:

ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 and 904L, etc.

For Alloy Pipe Reducer:

A234 WP1, WP5, WP9, WP11, WP22, WP91 etc.

2. Reducer Types

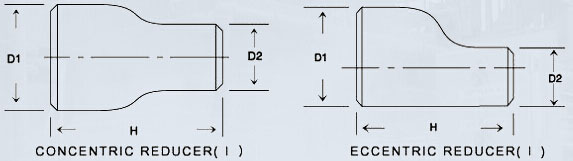

There are two types of reducer, concentric reducer and eccentric reducer.

Concentric Reducer

This reducer consists of the symmetrical and conical shaped fittings that enlarge or reduce the diameter equally about the center line. For an example, when 1” pipe transitions to ¾” pipe, then the top or bottom of the pipe do not remain level. It is widely used when single or multiple diameter changes.

Eccentric Reducer

A conically shaped fitting that reduces or enlarges the diameter, but it is not symmetrical about the center line. This is used in pipe-work systems for reducing the diameter of a pipe from one size to larger or small size.

Concentric Reducer vs Eccentric Reducer Differences

Concentric reducers are widely used while eccentric reducers are applied to maintain the top and bottom pipe level. Eccentric Reducers also avoids trapping of air inside the pipe, and Concentric Reducer removes noise pollution.

3. Manufacturing Process of Steel Pipe Reducer

There are versatile manufacturing processes for the reducers. These are made of welded pipes with the required filling material. However, EFW and ERW pipes cannot use the reducer. To manufacture forged parts, different kinds of methods are used including cold and hot forming processes. It includes the ‘Outer Die Method.’

4. Outer Dia Method

It is the most common method for manufacturing the steel pipe reducer. The pipe is cut and pressed in the outer die whereas, one end of the pipe is compressed into the smaller size. This method is fit for manufacturing small and medium-size reducers.

5. Connection Types of Pipe Reducer

Ranges from different connection types, pipe reducer could be classified with socket weld reducer and butt weld reducer.

Socket Weld Reducer vs Butt Weld Reducer

Socket weld reducer also called socket weld insert, it has three types 1, 2 and 3. Manufacturing standards comply to ASME B16.11.

The Socket Weld resists ½ of the strength of butt welding, so it is used for small-diameter pipes possessing a diameter of NPS 2 or less. Butt Weld has good strength, as it is suitable for high pressure and temperature pipelines.

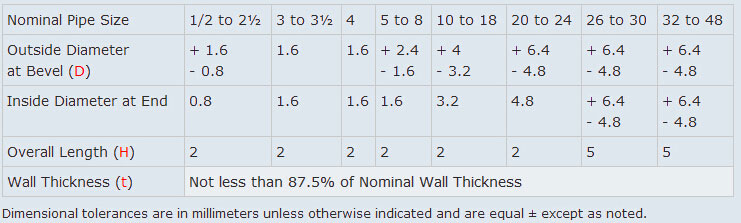

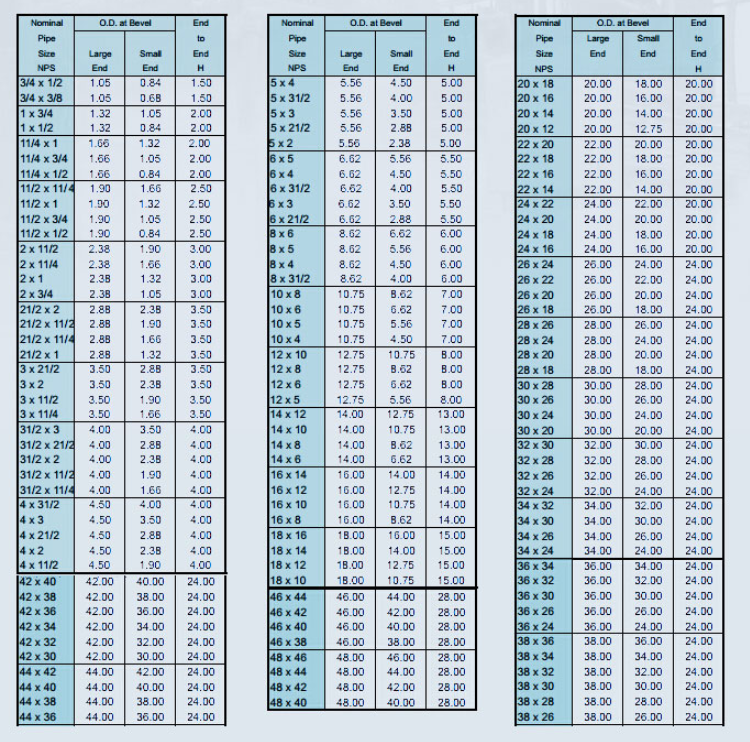

Butt weld reducer ends in plan or beveled, manufactured in accordance with ASME B16.9 and welding process according ASME B16.25.

6. Applications of Steel Pipe Reducer

The usage of a steel reducer is carried out in the chemical factories and power plants. It makes the piping system reliable and compact. It safeguards the piping system from any kind of adverse impact or thermal deformation. When it is on the pressure circle, it prevents from any type of leakage and is easy to install. The nickel or chrome coated reducers extends the product life, useful for high vapor lines, and prevents corrosion.

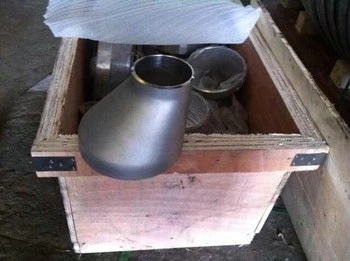

Pipe Reducer, Reducer Fittings

Steel Pipe Reducers available are of concentric and eccentric types. The pipe reducers are suitable components in pipelines that reduce pipe size from large to small bores. The inlet and outlet ends of the steel pipe reducers and alloy pipe reducers align to a common center line.

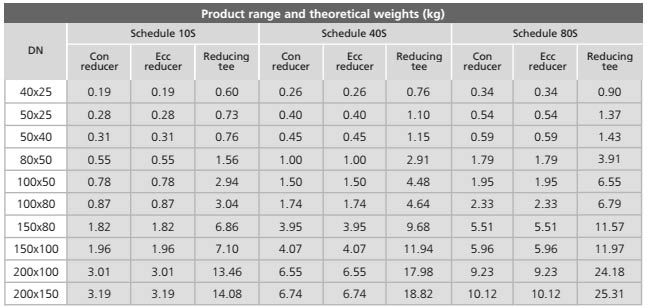

The reducers can be made of Carbon Steel, Alloy, or Stainless steel and much more. In comparison to the Stainless Steel Reducer, Carbon Steel Reducer possesses high-pressure resistance, higher strength, and wear resistant but this can be easily corroded.

Carbon Steel Reducer material standards and grades:

A234 WPB, A420 WPL6, MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 and 70.

For Stainless Steel Reducer:

ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 and 904L, etc.

For Alloy Pipe Reducer:

A234 WP1, WP5, WP9, WP11, WP22, WP91 etc.

Light Oiling, Black Painting