(1) ERW welded pipe from steel plate welding into the round pipe, divided into high frequency resistance welded pipe (ERW welded pipe), straight seam arc welding pipe (LSAW), spiral welded pipe.Electrical engineering with "SC", can be used as water gas pipe can also be used as threading pipe, relatively thick.

(2) Pipeline pipe, also known as wire pipe, is relatively thin, denoted by "T", and can only be used for thread. ERW steel pipe , Electric Resistance Welded Pipe

(3) ERW tube is "high frequency resistance welding steel tube", and the common welding process is different, the weld line is from the base material of the steel belt body melted, the mechanical strength is better than the general welded. ERW stands for resistance welding, resistance welding has the characteristics of high production efficiency, low cost, material saving and easy automation, so it is widely used in aviation, aerospace, energy, electronics, automotive, light industry and other industrial sectors, is one of the important welding processes.

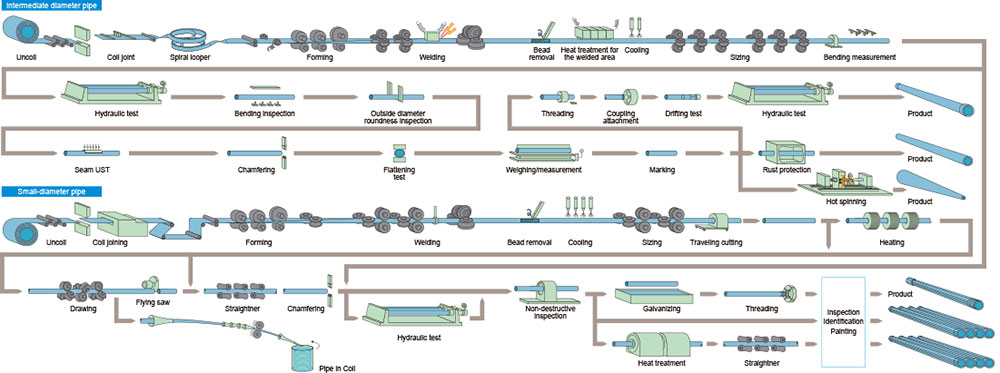

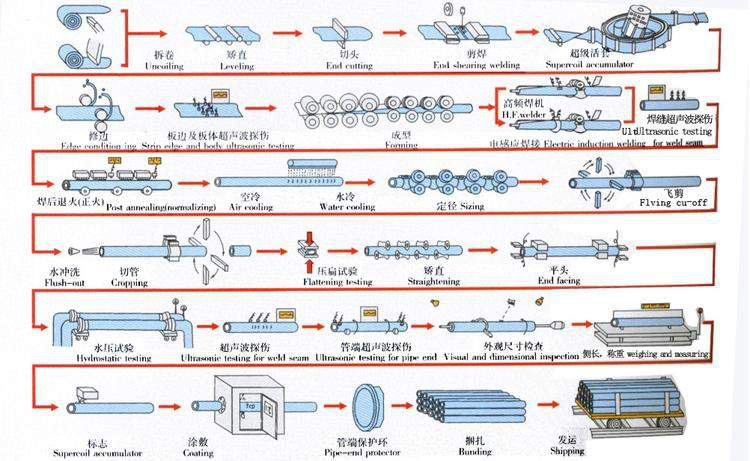

Production Process for ERW Steel Pipe:

- Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Super coil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming --- 9. Electric induction welding --- 10. Ultrasonic detection for weld seam --- 11. Medium frequency heat treatment --- 12. Air cooling --- 13. Water cooling --- 14. Sizing --- 15. Flying cutting --- 16. Flush-out --- 17. Cropping --- 18. Flattening testing --- 19. Straightening --- 20. End facing and bevelling --- 21. Hydrodynamic testing --- 22. Ultrasonic detection for weld seam --- 23. Ultrasonic detection for pipe end --- 24. Visual and dimensions inspection --- 25.Weighting and measuring --- 26. Marking --- 27. Coating --- 28. Pipe-end protection --- 29. Bending --- 30. Shipping

Main Characteristics of ERW Steel Pipes:

High-security welding seam: as a result of special welding method of melting of the parent metal together without filler metal, the welding property is better and the welding seam is much smaller than spiral welded pipes.

Cost effective and short production period

A wide range of thickness/diameter ratio, covering hundreds of specification

In –line inspection and testing

Application of ERW Pipes:

Casing and tubing: lined inside drilling well. Seamless pipes use to be the only choice for lining pipes inside drilling well, but as the worldwide acknowledgement of ERW pipe’s high-quality weld seam and the cost-effective, more and more projects have been choosing ERW instead of seamless pipe.

Constructional structural pipes(round, square and rectangular): round, square and rectangular ERW structural pipes are widely used in frameworks of shopping centres, theatres, airports, bridges, workshops etc.

Low-pressure flow transmitting: ERW pips are also used in water supply; cooling water supply for plants and equipment; low pressure thermal distributing; coal slurry transportation and more.

Pipes for raw materials in the manufacturing industry: automobile vent-pipe; low and intermediate pressure boiler pipes; bulk matters transportation pipes.

Other application: piling pipes, furniture fabricating and more.

|

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

|

|

|

|

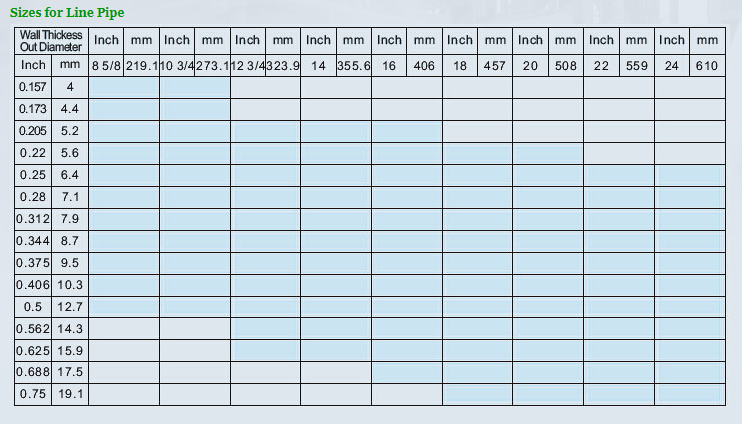

0.157 |

4 |

0.173 |

4.4 |

0.205 |

5.2 |

0.22 |

5.6 |

0.25 |

6.4 |

0.28 |

7.1 |

0.312 |

7.9 |

0.344 |

8.7 |

0.375 |

9.5 |

0.406 |

10.3 |

0.5 |

12.7 |

0.562 |

14.3 |

|

|

8 5/8 |

219.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

10 3/4 |

273.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

12 3/4 |

323.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

14 |

355.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

16 |

406 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

18 |

457 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

20 |

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

22 |

559 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

24 |

610 |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

OD |

WT |

|||||||||||||||||||||||||||||||

|

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

|

|

|

|

|

|

|

|

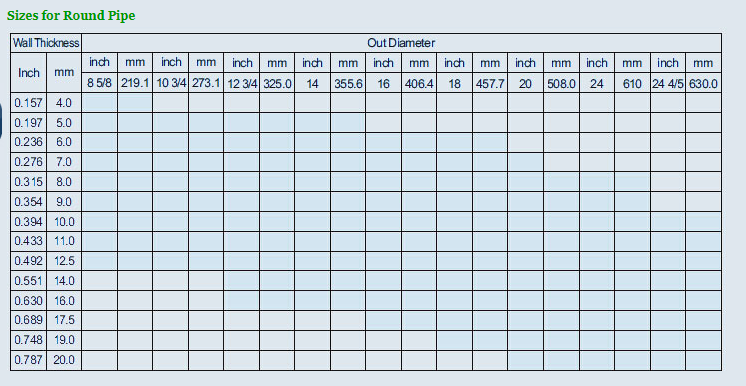

0.157 |

4 |

0.173 |

4.4 |

0.205 |

5.2 |

0.22 |

5.6 |

0.25 |

6.4 |

0.28 |

7.1 |

0.312 |

7.9 |

0.344 |

8.7 |

0.375 |

9.5 |

0.406 |

10.3 |

0.5 |

12.7 |

0.562 |

14.3 |

|

|

|

|

|

|

|||

|

8 5/8 |

219.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

10 3/4 |

273.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

12 3/4 |

323.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

14 |

355.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

16 |

406 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

18 |

457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

20 |

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

22 |

559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

24 |

610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

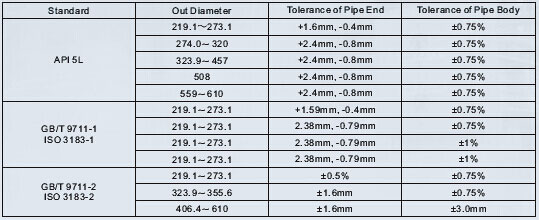

Tolerances of Outside Diameter – ERW Steel Pipe

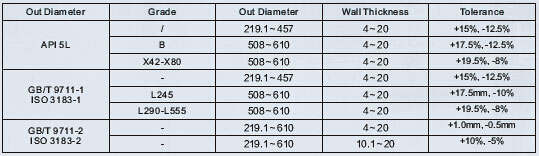

Tolerances of Wall Thickness – ERW Steel Pipe

Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings