Feature Description:

Slotted pipe works as a separator to filtrate the sand in oil or gas well, the main function is to control sand. Different grade and type (slotted, perforated, wire-wrapped and so on) of pipes will be applied for different stratum during oil and gas exploration.

Features:

1. A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2. Under the same condition, high open area can make the speed of groundwater’s entering into the screen much slower than any other filtration apparatus, which will avoid sand’s entering into screen because of high pressure, thus reduce the abrasion of the pump.

3. Our product have good character of anti-acid,anti-alkali and anti-corrosion,it can adapt to the oil well’s special demand.the crack won’t become bigger because of corrosion.it has good stability.

4. They have the features of easy backwashing, durable in use,safety and reliability as well as low comprehensive cost.

This laser slotted screen pipe used for petroleum. It can prevent 99% sand, decrease 80% of oil well heavy repair and increase the oil well's strength,integrality and stability of keeping off sand,Although its structure is simple,it's very effective. It has small cuts of 0.10—0.5mm in the tube wall

Main technical data:

Material: stainless steel, carbon steel

Categories of pipes: petroleum casing pipe, oil pipe

Length of pipe (single): ≤15m

Outside diameter of pipe: 50 to 200mm

Wall thickness ≤16mm

Width of slot: (0.10-0.40)mm±0.03mm

Number of slots: according to order

Distribution types of slots: parallel, crisscross, spiral

Distance of slots: according to order

Usage:

The slotted pipes using in oil exploration can prevent 99% sand, decrease 80% of oil well heavy repair and increase the oil well's strength, integrality and stability of keeping off sand. Meanwhile, the laser incision can make very small cuts with smooth surface and high precision. Although its structure is simple, it is very effective. It has small cuts of 0.10-0.5 mm in the tube wall.

1. Where well productivity is small and economics cannot support the use of screens;

2. Ideal for sand control for low fines and clay reservoirs;

3. Excellent sand control choice for thermal heavy oil &bitumen reservoirs;

4. Suitable for high CO2/H2S, SAGD, CSS, and CBM.

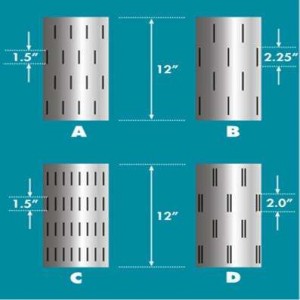

Slot Types

We are able to laser-cut slots as per customer specification, either as straight slots or keystone slots.

Straight Slots

Cut at a right angle to the liner, this slot type shows the same diameter from the inside to the outside of the wall. Although straight slots are cheaper to produce, they are less effective in sand control compared to keystone slots.

Keystone Slots

Cut at a slight angle, keystone slots, or tapered slots, are larger on the inside than on the outside, making sure that any particle entering the slot can pass through freely without clogging the slot.

Keystone slots are more expensive to than straight slots, but lower the risk of production losses due to plugged liner slots.

Slot Patterns

Whether you want your slotted pipe with a line, staggered, gang, overlapping, horizontal, or any other pattern, we can cut them all.

Among all slot patterns, the following three are the most common.

Line (Straight) Pattern

In the line pattern, slots are placed evenly in identical bands around the pipe, forming straight lines of slots across the length of the slotted liner.

Single-Slot Staggered Pattern

In the single-slot staggered pattern, bands of evenly spaced slots are placed around the pipe. Slots in different bands are offset (staggered) to each other.

The single-slot staggered pattern preserves the strength of the pipe and provides an even distribution of the slots over the area of the pipe.

Gang Pattern (Multiple Staggered Pattern)

While having the same overall layout as the single-slot staggered pattern, the gang pattern places two slots, cut at close proximity, instead of just one slot at each position.

Slotted pipe with a multiple staggered pattern has been shown to withstand higher torque during installation and provide better resistance to deformation under thermal load compared to the single-slot staggered pattern, making it well suited for application in steam assisted gravity drainage (SAGD) applications.

Popular Parameter(for reference):

|

API Casing |

ID |

Length |

Slot Length |

Slot No. |

Slot width |

Slot |

Valid Filter |

Max. |

||

|

Spec |

Thickness |

Per Weight |

||||||||

|

60.32 |

5 |

6.84 |

50.3 |

3 |

80 |

200 |

0.3 |

±50 |

48 |

512.54 |

|

73.02 |

5.5 |

9.15 |

62 |

240 |

57.6 |

688.55 |

||||

|

88.9 |

6.5 |

13.22 |

75.9 |

280 |

67.2 |

995.1 |

||||

|

101.6 |

6.5 |

15.22 |

88.6 |

300 |

72 |

1151.2 |

||||

|

114.3 |

7 |

18.47 |

100.3 |

10 |

320 |

76.8 |

1400.4 |

|||

|

127 |

7.52 |

22.13 |

112 |

340 |

81.6 |

1673.8 |

||||

|

139.7 |

7.72 |

25.11 |

124.3 |

360 |

86.4 |

1900.2 |

||||

|

9.17 |

29.48 |

121.4 |

360 |

86.4 |

2232.4 |

|||||

|

168.3 |

8.94 |

35.09 |

150.4 |

400 |

96 |

2672.95 |

||||

|

177.8 |

8.05 |

33.68 |

161.7 |

440 |

105.6 |

2559.2 |

||||

|

9.19 |

38.19 |

159.4 |

440 |

105.6 |

2940.7 |

|||||

Notice: Special sizes which customer required can be provided.

| Itema | Outside Diameter OD mm |

Nominal weight per unit length (threaded and coupling)b.c kb/m |

Wall Thickness mm |

End Finish | ||||||||

| 1 | 2 | H40 | J55 K55 |

M65 | L80 C95 |

N80 1, Q |

C90d T95d |

P110 | Q125d | |||

| 1 | 2 | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 41/2 41/2 41/2 41/2 41/2 |

9.50 10.50 11.60 13.50 15.10 |

114.30 114.30 114.30 114.30 114.30 |

14.14 15.63 17.26 20.09 22.47 |

5.12 5.69 6.35 7.37 8.56 |

PS — — — — |

PS PSB PSLB — — |

PS PSB PLB PLB — |

— — PLB PLB — |

— — PLB PLB — |

— — PLB PLB — |

— — PLB PLB PLB |

— — — — PLB |

| 5 5 5 5 5 5 5 |

11.50 13.50 15.00 18.00 21.40 23.20 24.10 |

127.00 127.00 127.00 127.00 127.00 127.00 127.00 |

17.11 19.35 22.32 26.79 31.85 34.53 35.86 |

5.59 6.43 7.52 9.19 11.10 12.14 12.70 |

— — — — — — — |

PS PSLB PSLBE — — — — |

PS PSLB PLB PLB PLB — — |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — PLBE PLBE PLB PLB PLB |

— — — PSLB PLB PLB PLB |

| 51/2 51/2 51/2 51/2 51/2 51/2 51/2 51/2 51/2 51/2 51/2 51/2 |

14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 |

139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 |

20.83 23.07 25.30 19.76 34.23 39.88 44.20 48.51 52.53 56.55 60.27 61.14 |

6.20 6.98 7.72 9.17 10.54 12.70 14.27 15.88 17.45 19.05 20.62 22.22 |

PS — — — — — — — — — — — |

PS PSLBE PSLBE — — — — — — — — — |

PS PSLB PLB PLB PLB — — — — — — — |

— — PLBE PLBE PLBE — — — — — — — |

— — PLBE PLBE PLBE — — — — — — — |

— — PSBE PSBE PSBE P P P P P P P |

— — PLBE PLBE PLBE — — — — — — — |

— — — — PLBE — — — — — — — |

| 65/8 65/8 65/8 65/8 |

20.00 24.00 28.00 32.00 |

168.28 168.28 168.28 168.28 |

29.76 35.72 41.67 47.62 |

7.32 8.94 10.59 12.06 |

PS — — — |

PSLB PSLBE — — |

PSLB PLB PLB — |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— PLBE PLBE PLBE |

— — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 |

17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 |

177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 177.80 |

25.30 29.76 34.23 38.69 43.16 47.62 52.09 56.55 63.54 69.05 74.56 79.77 84.97 |

5.87 6.91 8.05 9.19 10.36 11.51 12.65 13.72 15.88 17.45 19.05 20.62 22.22 |

PS PS — — — — — — — — — — — |

— PS PSLBE PSLBE — — — — — — — — — |

— PS PLB PLB PLB PLB — — — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — |

— — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P |

— — — PLBE PLBE PLBE PLBE PLBE — — — — — |

— — — — — — PLBE PLBE — — — — — |

| 75/8 75/8 75/8 75/8 75/8 75/8 75/8 75/8 75/8 75/8 |

24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 |

193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 |

35.72 39.29 44.20 50.15 58.04 63.69 67.41 70.09 76.19 19.05 |

7.62 8.33 9.52 10.92 12.70 14.27 15.11 15.88 17.45 19.05 |

PS — — — — — — — — — |

— PSLBE — — — — — — — — |

— PSLB PLB PLB — — — — — — |

— PLBE PLBE PLBE PLBE PLB PLB PLB — — |

— PLBE PLBE PLBE PLBE PLB PLB PLB — — |

— PLBE PLBE PLBE PLBE PLB PLB PLB P P |

— PLBE PLBE PLBE PLBE PLB PLB PLB — — |

— — — — PLBE PLB PLB PLB — — |

| 73/4 | 46.10 | 196.85 | 68.60 | 15.11 | — | — | — | P | ||||

| 85/8 85/8 85/8 85/8 85/8 85/8 85/8 |

24.00 28.00 32.00 36.00 40.00 44.00 49.00 |

219.08 219.08 219.08 219.08 219.08 219.08 219.08 |

35.72 41.67 47.62 53.57 59.53 65.48 72.92 |

6.71 7.72 8.94 10.16 11.43 12.70 14.15 |

— PS PS — — — — |

PS — PSLBE PSLBE — — — |

PS PS PSLB PSLB PLB — — |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

— — — PLBE PLBE PLBE PLBE |

| 95/8 95/8 95/8 95/8 95/8 95/8 95/8 95/8 95/8 95/8 95/8 |

32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 |

244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 |

48.07 5357 59.53 64.73 69.94 79.62 86.91 88.40 98.58 104.62 112.50 |

7.92 8.94 10.03 11.05 11.99 13.84 15.11 15.47 17.07 18.64 20.24 |

PS PS — — — — — — — — — |

— PSLBE PSLBE — — — — — — — — |

— PSLB PSLB PLB PLB — — — — — — |

— — PLBE PLBE PLBE PLBE PLB — — — — |

— — PLBE PLBE PLBE PLBE PLB — — — — |

— — PLBE PLBE PLBE PLBE PLB P P p P |

— — PLBE PLBE PLBE PLBE PLB — — — — |

— — PLBE PLBE PLBE PLBE PLB P P p P |

| 103/4 103/4 103/4 103/4 103/4 103/4 103/4 103/4 103/4 103/4 |

32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 |

273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 |

48.74 60.27 67.71 75.90 82.69 90.33 97.77 108.93 117..86 126.94 |

7.09 8.89 10.16 11.43 12.57 13.84 15.11 17.07 18.64 20.24 |

PS PS — — — — — — — — |

— PSB PSBE PSBE — — — — — — |

— PSB PSB PSB PSB — — — — — |

— — — PSBE PSBE — — — — — |

— — — PSBE PSBE — — — — — |

— — — PSBE PSBE PSBE PSBE P P P |

— — — PSBE PSBE PSBE PSB — — — |

— — — PSBE PSBE PSBE PSBE P P P |

| 113/4 113/4 113/4 113/4 113/4 113/4 |

42.00 47.00 54.00 60.00 65.00 71.00 |

298.45 298.45 298.45 298.45 298.45 298.45 |

62.50 69.94 80.36 89.29 96.37 105.66 |

8.46 9.53 11.05 12.42 .13.56 14.78 |

PS — — — — — |

— PSB PSB PSB — — |

— PSB PSB PSB — — |

— — — PSB P P |

— — — PSB P P |

— — — PSB P P |

— — — PSB P P |

— — — PSB P P |

| 133/8 133/8 133/8 133/8 133/8 |

48.00 54.50 61.00 68.00 72.00 |

339.72 339.72 339.72 339.72 339.72 |

71.43 81.10 90.78 101.19 107.15 |

8.38 9.65 10.92 12.19 13.06 |

PS — — — — |

— PSB PSB PSB — |

— PSB PSB PSB — |

— — — PSB PSB |

— — — PSB PSB |

— — — PSB PSB |

— — — PSB PSB |

— — — — PSB |

| 16 16 16 16 |

65.00 75.00 84.00 109.00 |

406.40 406.40 406.40 406.40 |

96.73 111.61 125.01 162.21 |

9.53 11.13 12.57 16.66 |

PS — — — |

— PSB PSB P |

— PSB PSB — |

— — — P |

— — — P |

— — — P |

— — — P |

— — — P |

| 185/8 | 87.50 | 473.08 | 130.21 | 11.05 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 |

94.00 106.50 133.00 |

508.00 508.00 508.00 |

139.89 158.49 197.93 |

11.13 12.70 16.13 |

PSL — — |

PSLB PSLB PSLB |

PSLB PSLB — |

— — — |

— — — |

— — — |

— — — |

— — — |

| Note: P—Flat End; S—short round thread; L—long round thread; B—buttress thread; E—straight-through type | ||||||||||||

| a stands for ordering code for reference. b stands for the nominal weight per unit length (threaded and coupling) for reference only c Density of martensitic chromium steel (L80 9R and 13R) is different from carbon steel. Therefore, nominal line weight is not an accurate value and its mass (weight) correction factor is 0.989. d Steel casing of C90, T95 and Q125 are ordered according to the specifications, mass (weight) and wall thickness shown in the table. |

||||||||||||

API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

| Specifications of Different Standards | ||||||||

| Chinese Unit | English Unit | |||||||

| Outside Diameter | Wall Thinkness | Outside Diameter | Wall Thinkness | |||||

| 21.3mm-508mm | 4mm-60mm | 1/2” – 14” | Sch40-XXS | |||||

| Material and standard | ||||||||

| Item | Chinese Standard | American Standard | German Standard | |||||

| (1) | 10# | A53-A | St37 | DIN1626 | ||||

| A106-A | St37-2 | DIN17175 | ||||||

| A179-C | St35.8 | DIN17175 | ||||||

| (2) | 20# | ASTM A 106-B | St45-8 | DIN17175 | ||||

| ASTM A 53-B | St42-2 | DIN1626 | ||||||

| ASTM 178-C | St45-4 | DIN1626 | ||||||

| (3) | 45# | ASTM A1045 | CK45 | |||||

| (4) | 16Mn | A210-C | St52.4 | DIN1629 | ||||

| St52 | DIN1629 | |||||||

| (5) | 37Mn5 | J55 | ||||||

| Application | Used in petroleum, chemical, electric power, coal, machinery, high and low pressure boiler pipe, hydraulic prop, marine and other industries | |||||||

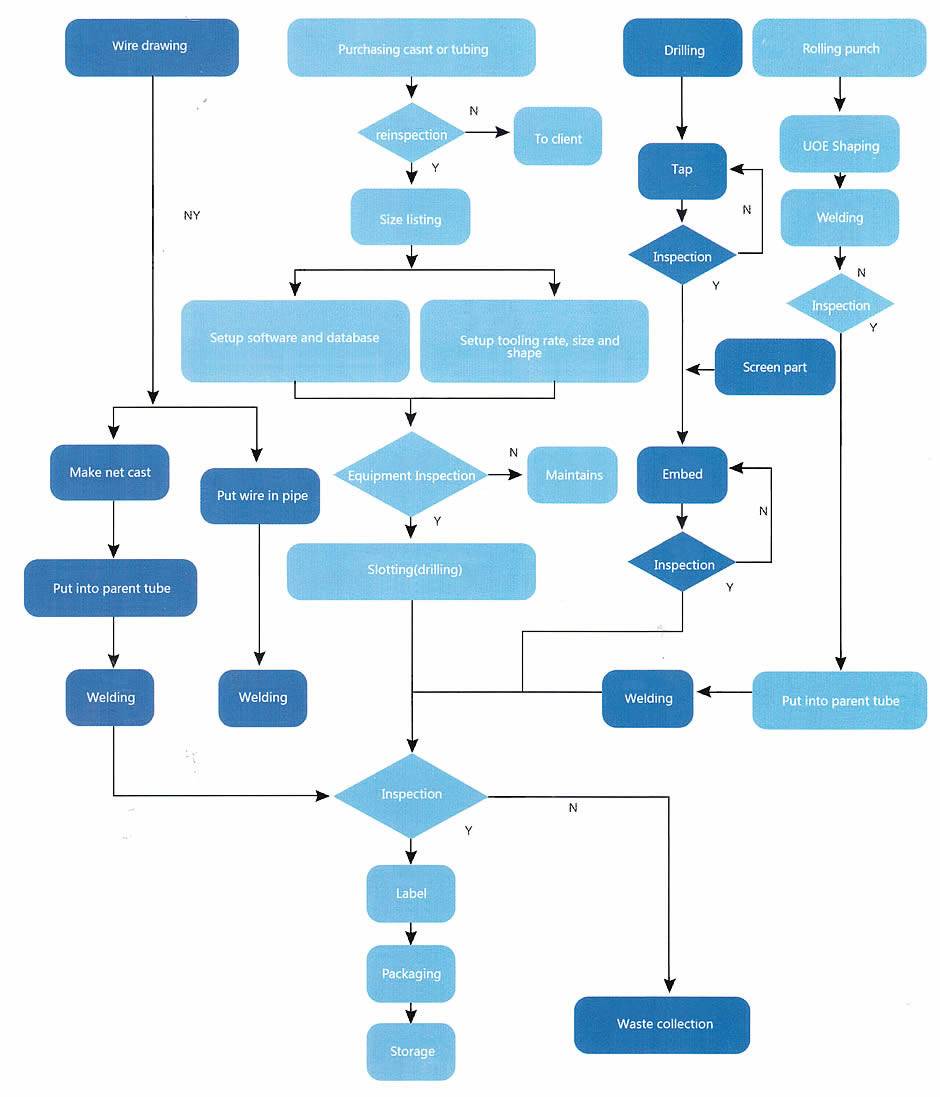

Process flow of screen pipe processing

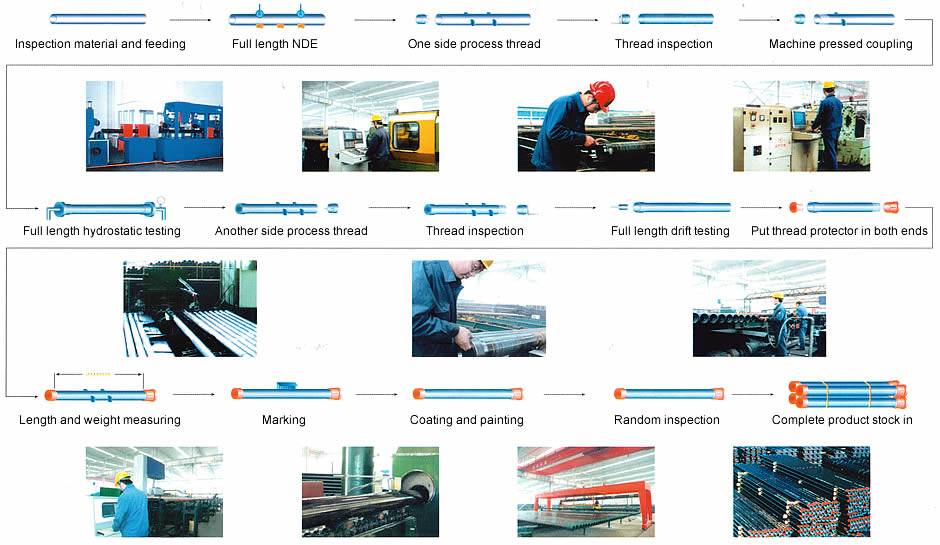

The process flowchart of tubing/casing machining