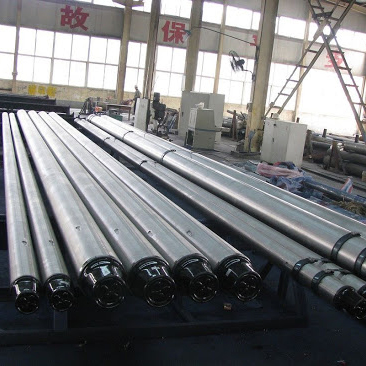

Drill collars are extra-heavy integral tools used to concentrate weight onto the drill bit so as to produce sufficient force for the drill bit to break rock efficiently while drilling. They are made of AISI 4145H modified steel and are connected between drill pipes and drill bits.

Drill collars come in 30 or 31 foot lengths and are furnished as slick (as-rolled surface finish) or spiraled. Spiraled drill collars have grooves on its external surface which maintains an even flow of drilling fluid around the collar to equalize pressure and reduce differential-sticking of the collar to the wall of the oilwell.

Our drill collar connections comply with dimensional requirements specified in API Spec. 7/7-1 and guidelines presented in API RP7G. Drill collars also come with slip and elevator recesses for safe and efficient handling. Slip and elevator recesses can be used together or separately and are machined in compliance with API RP7G guidelines unless otherwise specified.

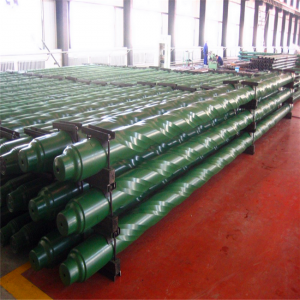

NON-MAGNETIC DRILL COLLARS

TECHNICAL SUMMARY

As you drill in areas closer to the earth's magnetic poles, it is essential to use a non-magnetic drill collar. Our non-mag drill collars offer strength and hardness while neutralizing magnetic inference. Compatible with standard drill string tools and stabilizers, our non mag drill collars are manufactured to API Spec 7-1. Inventory includes:

(1)Slick

(2)Flex

(3)Spiral

(4)Pony

We treat our non-mag material ID with a shot peening operation to compress the inside diameter which prevents stress corrosion while drilling in H2S environments.

Resistant to stress corrosion in sour gas environments

Compatible with standard drill string tools and stablizers

Spiraling available on request

Used to add weight to the bit and stiffness to bottom hole assembly, our Drill Collars are an invaluable downhole tool.

STEEL DRILL COLLARS

To keep you drilling in the right direction, run our Drill Collars in combination with our Stabilizers to resist bucking. Manufactured from an AISI 4145H modified heat treated alloy steel, our strict quality assurance guidelines assure metallurgical integrity of each and every bar.

Our Drill Collar bars are batch or continuous line heat treated and have both cold-worked and Phosphate coated connections.

NON-MAGNETIC DRILL COLLARS

|

Common Connections |

OD (in) |

ID (in) |

Approx Weight (lbs) |

|

2 7/8 REG |

3 1/2 to 3 7/8 |

1 1/4 to 1 3/4 |

760-1114 |

|

3 1/2 REG |

4 1/8 to 4 1/2 |

1 1/4 to 2 1/4 |

989-1490 |

|

3 1/2 IF NC38 |

4 3/4 to 5 1/2 |

1 3/4 to 2 13/16 |

1350-2250 |

|

4 FH NC40 |

5 to 6 |

1 3/4 to 2 13/16 |

1552-2726 |

|

4 1/2 FH |

5 1/2 to 6 1/2 |

2 to 3 |

1759-3166 |

|

4 1/2 XH NC46 |

5 3/4 to 6 3/4 |

2 1/4 to 3 |

1992-3352 |

|

4 1/2 IF NC50 |

6 1/4 to 7 1/2 |

2 1/4 to 3 1/4 |

2359-4237 |

|

5 1/2 FH NC56 |

7 to 7 3/4 |

2 1/4 to 3 1/4 |

3182-4552 |

|

6 5/8 REG |

7 1/4 to 8 |

2 1/2 to 3 1/4 |

3476-4780 |

|

6 5/8 FH |

7 1/2 to 8 1/4 |

2 1/2 to 3 1/4 |

3782-5116 |

|

7 5/8 REG |

8 1/2 to 9 1/2 |

2 1/2 to 3 3/4 |

4816-6953 |

STEEL DRILL COLLARS

|

O.D. (in) |

I.D. (in) |

Weight in Air (lbs) |

Unit Weight (lbs/ft) |

Standard End Connections |

|

3 1/2 |

1 1/2 |

826.8 |

26.7 |

NC-26 thru 35 |

|

4 1/8 |

2 |

1076.2 |

34 |

NC-31 thru 41 |

|

4 3/4 |

2 1/4 |

1447.0 |

46.7 |

NC-38 thru 47 |

|

5 |

2 1/4 |

1648.5 |

53.2 |

NC-38 thru 50 |

|

6 |

2 1/4 |

2558.0 |

82.5 |

NC-44 thru 60 |

|

6 |

2 13/16 |

2322.3 |

74.9 |

NC-44 thru 60 |

|

6 1/4 |

2 1/4 |

2811.2 |

90.7 |

NC-44 thru 62 |

|

6 1/4 |

2 13/16 |

2575.6 |

83.1 |

NC-46 thru 65 |

|

6 1/2 |

2 1/4 |

3074.8 |

99.2 |

NC-46 thru 65 |

|

6 1/2 |

2 13/16 |

2839.1 |

91.6 |

NC-46 thru 65 |

|

6 3/4 |

2 1/4 |

3348.7 |

108.0 |

NC-46 thru 67 |

|

7 |

2 1/4 |

3632.9 |

117.2 |

NC-50 thru 70 |

|

7 |

2 13/16 |

3397.2 |

109.6 |

NC-50 thru 70 |

|

7 1/4 |

2 13/16 |

3691.8 |

119.1 |

NC-50 thru 72 |

|

8 |

2 13/16 |

4637.5 |

149.6 |

6 5/8 Regular |

|

8 1/4 |

2 13/16 |

4973.4 |

160.4 |

6 5/8 Regular |

|

9 1/2* |

3 |

6718.0 |

216.7 |

7 5/8 Regular |

|

9 3/4* |

3 |

7116.0 |

229.5 |

7 5/8 Regular |

|

11* |

3 |

9260.6 |

298.7 |

8 5/8 Regular |

RECOMMENDED SLIP AND ELEVATOR RECESS DIAMETERS FOR DRILL COLLARS

|

Standard |

Number |

OD |

ID |

Length |

Weight |

Typical Bending |

|

SY5144-2007/API7-1 |

NC 23-31 |

3-1/8 |

1-1/4 |

30 |

22 |

2.57:1 |

|

NC 26-35 (2-3/8 IF) |

3-1/2 |

1-1/2 |

30 |

27 |

2.42:1 |

|

|

NC 31-41 (2-7/8 IF) |

4-1/8 |

2 |

30 or 31 |

34 |

2.43:1 |

|

|

NC 35-47 |

4-3 /4 |

2 |

30 or 31 |

47 |

2.58:1 |

|

|

NC 38-50 (3-1/2 IF) |

5 |

2-1/4 |

30 or 31 |

54 |

2.38:1 |

|

|

NC 44-60 |

6 |

2-1/4 |

30 or 31 |

83 |

2.49:1 |

|

|

NC 44-60 |

6 |

2-13 /16 |

30 or 31 |

76 |

2.84:1 |

|

|

NC 44-62 |

6-1/4 |

2-1/4 |

30 or 31 |

91 |

2.91:1 |

|

|

NC 46-62 (4 IF) |

6-1/4 |

2-13 /16 |

30 or 31 |

84 |

2.63:1 |

|

|

NC 46-65 (4 IF) |

6-1/2 |

2-1/4 |

30 or 31 |

100 |

2.76:1 |

|

|

NC 46-65 (4 IF) |

6-1/2 |

2-13 /16 |

30 or 31 |

93 |

3.05:1 |

|

|

NC 46-67 (4 IF) |

6-3 /4 |

2-1/4 |

30 or 31 |

109 |

3.18:1 |

|

|

NC 50-70 (4-1/2 IF) |

7 |

2-1/4 |

30 or 31 |

118 |

2.54:1 |

|

|

NC 50-70 (4-1/2 IF) |

7 |

2-13 /16 |

30 or 31 |

111 |

2.73:1 |

|

|

NC 50-72 (4-1/2 IF) |

7-1/4 |

2-13 /16 |

30 or 31 |

120 |

3.12:1 |

|

|

NC 56-77 |

7-3 /4 |

2-13 /16 |

30 or 31 |

140 |

2.70:1 |

|

|

NC 56-80 |

8 |

2-13 /16 |

30 or 31 |

151 |

3.02:1 |

|

|

6-5/8 API Reg |

8-1/4 |

2-13 /16 |

30 or 31 |

162 |

2.93:1 |

|

|

NC 61-90 |

9 |

2-13 /16 |

30 or 31 |

196 |

3.17:1 |

|

|

7-5/8 API Reg |

9-1/2 |

3 |

30 or 31 |

217 |

2.81:1 |

|

|

NC 70-97 |

9-3 /4 |

3 |

30 or 31 |

230 |

2.57:1 |

|

|

NC 70-100 |

10 |

3 |

30 or 31 |

243 |

2.81:1 |

|

|

8-5/8 API Reg |

11 |

3 |

30 or 31 |

300 |

2.84:1 |

NON-MAGNETIC DRILL COLLARS

|

Room Temperature. ASTM A 370 |

||||||||

|

Drill Collar OD Range |

Min. Yield Strength |

Min. Tensile Strength |

Min. Elongation % |

Impact Test CHARPY V. notch |

||||

|

MPa |

PSI |

MPa |

PSI |

J (min.) |

ft-lbs (min.) |

|||

|

2 3/4″ thru 3 7/8″ |

827 |

120 000 |

896 |

130 000 |

16 |

81 |

60 |

|

|

4″ thru 6 7/8″ |

758 |

110 000 |

827 |

120 000 |

18 |

|||

|

7″ thru 11″ |

689 |

100 000 |

758 |

110 000 |

20 |

|||

STEEL DRILL COLLARS

|

Room Temperature. ASTM 4145 H Modified |

||||||||

|

Drill Collar OD Range |

Min. Yield Strength |

Min. Tensile Strength |

Min. Elongation % |

Impact Test CHARPY V. notch |

Hardness (Brinell) |

|||

|

MPa |

PSI |

MPa |

PSI |

J (min.) |

ft-lbs (min.) |

HBN |

||

|

3 1/8″ thru 6 7/8″ |

758 |

110 000 |

965 |

140 000 |

13 |

54 |

40 |

285-341 |

|

7″ thru 11″ |

689 |

100 000 |

930 |

135 000 |

||||