What is Drill Pipe?

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3).

How to Work with Drilling Pipe?

The drilling tool is connected drill rod for transferring power. The drill string is usually part are: drill, drill collars, drilling pipe, stabilizers, special connectors and Kelly. The basic role of the drill string are: (1)control the drill bit; (2) imposed WOB; (3) transmission of power; (4) transporting drilling fluid; (5) special operations: extrusion of cement, handling underground accidents.

Drilling pipe is trailing with screw thread for connecting the drilling rig located at the bottom of surface drilling equipment and mill equipment or bottom outlet device. The purpose is to drill the drilling mud delivered to the drill bit, and drill with the increase, decrease or rotating bottom outlet means. Drill pipes must be able to withstand great external pressure, twisting, bending and vibration. In the mining and oil and gas refining process, the drill pipe can be used multiple times.

Drill Pipe: Drill pipe includes pipe body and tool joints(box and pin) welded together, used to connect drilling rig surface equipment and bottom equipment or bottom hole equipment. Drill pipe can bear heavy internal and external pressure, and twist, bend and vibration which can be used more than one time during oil or gas production.

Drill pipes are steel tube fitted with threaded ends called tool joints, which are commonly used in tension in the top part of the drill string to pump fluid and transmit torque to the bit.

Standard: Drill pipe

Grade: E75, X95, G105, S135

The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT

Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Usage: Mine blasting, water well drilling, geothermal wells drilling, fore poling, coal and nonferrous metal mining projects, etc.

API 5DP Specification is under the jurisdiction of the API Committee on Standardization ofTubular Goods. The purpose of this specification is to provide standards for drill pipe suitable for use in drilling and producing operations.

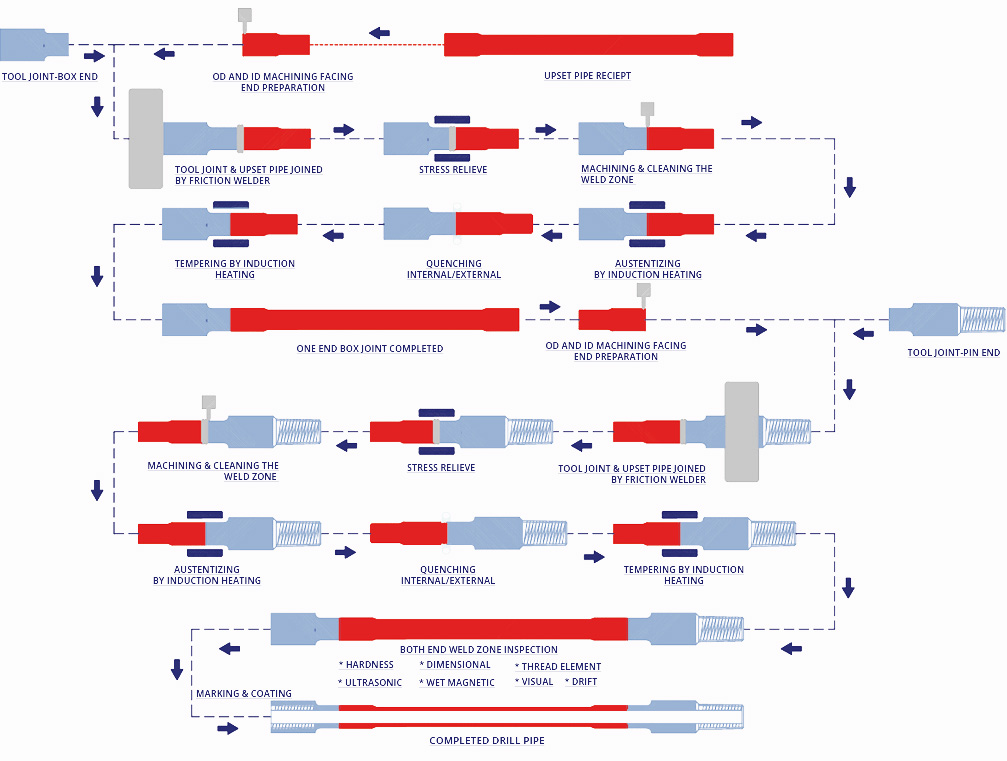

Special Processes of API 5DP Specification for Drill Pipe Special Processes are the final operations which are performed during pipe manufacturing that affect attribute compliance required in this document (except chemistry and dimensions). The applicable special processes are heat treatment, nondestructive testing, and, if applicable, cold finishing

Dimension:

|

Size designation |

Calculated weight |

Tool joint designation |

Calculated weight |

grade |

Wall thickness |

Upset ends |

||

|

in |

1b/ft |

Kg/m |

in |

mm |

||||

|

2 3/8 |

6.65 |

NC26 |

6.26 |

9.32 |

E.X.G.S |

0.28 |

7.11 |

EU |

|

2 7/8 |

10.4 |

NC31 |

9.72 |

14.48 |

E.X.G.S |

0.362 |

9.19 |

EU |

|

3 1/2 |

13.3 |

NC38 |

12.31 |

18.34 |

E.X.G.S |

0.368 |

9.35 |

EU |

|

3 1/2 |

15.5 |

NC38,NC40 |

14.63 |

21.79 |

E.X.G.S |

0.449 |

11.4 |

EU |

|

4 |

14 |

NC40,NC46 |

12.93 |

19.26 |

E.X.G.S |

0.33 |

8.38 |

IU,EU |

|

4 1/2 |

16.6 |

NC46,NC50 |

14.98 |

22.31 |

E.X.G.S |

0.337 |

8.56 |

EU,IEU |

|

4 1/2 |

20 |

NC46,NC50 |

18.69 |

27.84 |

E.X.G.S |

0.43 |

10.92 |

EU,IEU |

|

5 |

19.5 |

NC50,NC52 |

17.93 |

26.71 |

E.X.G.S |

0.362 |

9.19 |

IEU |

|

5 |

25.6 |

NC50,5 1/2FH |

24.03 |

35.79 |

E.X.G.S |

0.5 |

12.7 |

IEU |

|

5 1/2 |

21.9 |

5 1/2FH |

19.81 |

29.51 |

E.X.G.S |

0.361 |

9.17 |

IEU |

|

5 1/2 |

24.7 |

5 1/2FH |

22.54 |

33.57 |

E.X.G.S |

0.415 |

10.54 |

IEU |

|

6 5/8 |

25.2 |

6 5/8FH |

22.19 |

33 |

E.X.G.S |

0.33 |

8.387 |

IEU |

|

6 5/8 |

27.7 |

6 5/8FH |

24.21 |

41 |

E.X.G.S |

0.362 |

9.19 |

IEU |

Chemical Composition(%):

|

Grade |

Chemical composition |

|

|

P |

S |

|

|

E75 |

<0.015 |

<0.003 |

|

X95 |

<0.015 |

<0.003 |

|

G105 |

<0.015 |

<0.003 |

|

S135 |

<0.015 |

<0.003 |

|

Tool joint |

<0.015 |

<0.003 |

Mechanical Properties:

|

Pipe body |

Grade |

Yield strength |

Tensile strength |

Elongation |

Hardness |

Full size charpy impact test(J) |

||||||

|

min |

max |

min |

min |

|||||||||

|

Psi |

MPa |

Psi |

MPa |

Psi |

MPa |

HBW |

HRC |

Average |

Single |

|||

|

E75 |

75000 |

517 |

105000 |

724 |

100000 |

689 |

625000A0.2/ U0.9 |

- |

- |

80 |

65 |

|

|

X95 |

95000 |

655 |

125000 |

862 |

105000 |

724 |

- |

- |

80 |

65 |

||

|

G105 |

105000 |

724 |

135000 |

931 |

115000 |

793 |

- |

- |

80 |

65 |

||

|

S135 |

135000 |

931 |

165000 |

1138 |

145000 |

1000 |

- |

- |

80 |

65 |

||

|

Weld zone |

Tool joint |

120000 |

827.4 |

- |

- |

140000 |

965.3 |

=13% |

=285 |

- |

80 |

65 |

|

E75 |

75000 |

517 |

- |

- |

100000 |

689 |

- |

?37 |

40 |

27 |

||

|

X95 |

88000 |

609 |

- |

- |

103000 |

712 |

- |

?37 |

40 |

27 |

||

|

G105 |

95000 |

655 |

- |

- |

105000 |

724 |

- |

?37 |

40 |

27 |

||

|

S135 |

105000 |

724 |

- |

- |

115000 |

?37 |

40 |

27 |

||||

Anti-Corrosion Water Based Paint