-

Q345b steel polishing method

Q345b steel polishing method often used Polishing means a processing method by the action of mechanical, chemical or electrochemical, lower the q345b steel pipe surface roughness, to obtain a bright and smooth surface, and surface modification process making use of a flexible polishing tools and ...Read more -

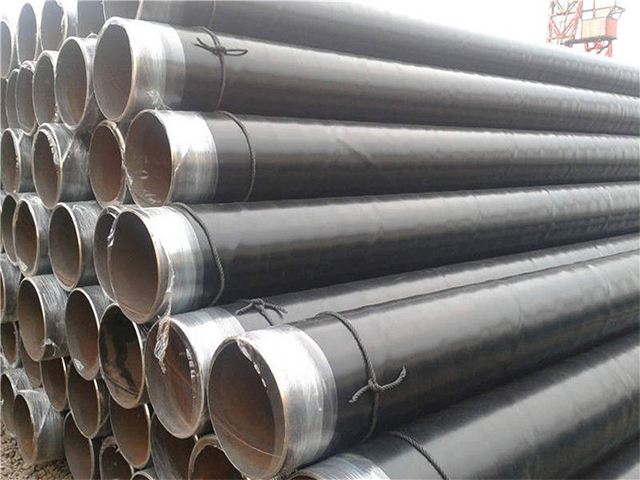

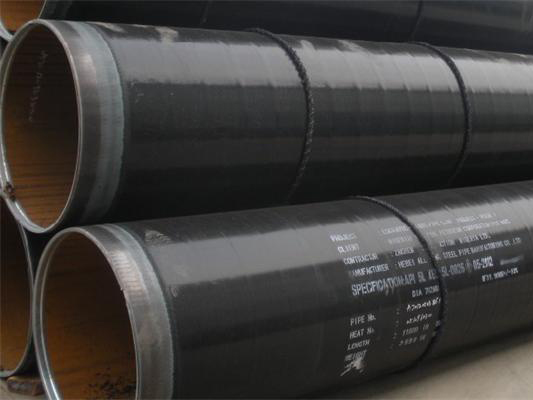

Polyethylene Coated Steel Pipe

Polyethylene coated steel pipe is the base pipe through a special process, the outer surface coated with a special polyethylene plastic powder materials in the tube prepared with antistatic, flame retardant, anticorrosive properties of composite products, overcome the steel itself are easy to rus...Read more -

Pressure pipe wall thickness select and stress

It is the most basic and common problem to choose the wall thickness for pressure pipe. but in the actual design process is very confusing, often messed SCH table, not through calculus free to apply some manual data phenomenon empirically estimate , as well as the pipe wall thickness, the bigger ...Read more -

Pipe bender

Pipe bender can be divided into CNC bending machine, hydraulic pipe bender, and so on. Mainly used in power and construction, public railway construction, boilers, bridges, ships, furniture, decoration and other aspects of the pipeline and build, with a multi-function, reasonable structure, easy ...Read more -

Piling pipe production process

Spiral Pipe is a strip coil as raw material, often warm extrusion molding, automatic double wire-sided submerged arc welding process welded spiral seam steel pipe. (1) raw materials that strip, wire, flux. We must go through rigorous physical and chemical testing before it is put. (2) strip head ...Read more -

Steel Pipe for Piling

Piling pipe is also known as pipe, welded steel pipe made of steel sheet or strip after curl after forming divided into Longitudinal and spiral welded pipe; the welding process is divided into stove pipe, welded pipe and automatic arc welded pipe, pipe materials and for different purposes is divi...Read more -

Steel Industry is Moving towards a New Era

At present, the global steel industry is moving towards a new historical period, China’s steel consumption has begun to enter the stage of reduction. All along, China’s iron and steel industry to conscientiously implement the Party Central Committee and the State Council’s decis...Read more -

Pipe phosphate process

Thermal phosphoric acid process uses yellow phosphorus as raw materials with electrothermal production, made of phosphoric acid with content of 85% by Combustion water. Thermal phosphoric acid production process with a heat recovery unit, usually two-step method, ie the combustion of phosphorus...Read more -

Process notes of lsaw steel pipe

Process notes of lsaw steel pipe: (1) Longitudinal volume of raw materials ie steel, wire, flux. Go through rigorous physical and chemical testing before it is put. (2) Strip head and tail docking, a single wire or twin-wire submerged arc welding, in the rolled back using automatic submerged arc ...Read more -

Piping and Plumbing Fitting

A fitting is used in pipe systems to connect straight pipe or tubing sections, adapt to different sizes or shapes and for other purposes, such as regulating {or measuring) fluid flow. “Plumbing” is generally used to describe the conveyance of water, gas, or liquid waste in domestic or...Read more -

Pipe sleeve

Pipe sleeve is generally more than actually used a large steel pipe. pipe sleeve is generally one of three things: a protective ring used to keep a pipe hole open, a ring used to fill the gap between a pipe and another surface, or a covering to create a barrier between a pipe and its surroundings...Read more -

Hardness testing methods of high-pressure boiler tubes

High pressure boiler tube hardness testing should take into account its mechanical properties, which is related to stainless steel as raw material for the deformation, such as punching, cutting processing performance and quality. Therefore, all of the high-pressure boiler tubes need to conduct me...Read more