-

Explore the advantages and applications of 219mm seamless steel pipes

In the steel industry, 219mm seamless steel pipes, as an important pipe product, have unique advantages and wide applications. Let us explore these advantages and application areas in depth to understand the importance of this steel pipe in the industrial and construction fields. Characteristics ...Read more -

Characteristics and causes of eight defects in Seamless Steel Pipes

If there are some defects in seamless steel pipes, it will undoubtedly have a fatal impact on the quality of our products. So how to avoid these defects? 1. Folding of seamless steel pipes: a state that exists on the outer or inner surface of seamless steel pipes, in a straight or spiral, continu...Read more -

What are the connections and differences between normalizing and annealing steel pipes

What is the normalizing of steel pipes? Normalizing steel pipes is a heat treatment to improve the toughness of steel pipes. After heating the steel component to 30~50℃ above the Ac3 temperature, keep it warm for a period of time and then air cool it out of the furnace. The main feature is that t...Read more -

How to improve the hardness of cold-rolled steel plates

First, what is the hardness of cold-rolled steel plates: 1. Ordinary cold-rolled steel plates: The hardness range of ordinary cold-rolled steel plates is generally between HRB1/2H=74~89 and 1/4H=65~80. Among them, HRB refers to Rockwell hardness, which is a standard for measuring the hardness of ...Read more -

Production process of anti-corrosion steel pipe

First, what materials are anti-corrosion steel pipes made of Anti-corrosion pipes are generally also called anti-corrosion steel pipes. They refer to steel pipes that have been processed by anti-corrosion technology and can effectively prevent or slow down corrosion caused by chemical or electroc...Read more -

Process details of square steel pipes and galvanized steel pipes

1. Calculation formula for theoretical weight of square steel pipes The theoretical weight of galvanized square pipes can be calculated by a calculation formula: 4*wall thickness*(side length-wall thickness)*7.85=weight per meter (g/m). The side length and wall thickness are both in millimeters. ...Read more -

Industrial project performance of oil well pipes

The performance of oil well pipes includes anti-galling performance, anti-collapse performance, anti-corrosion performance, and perforation performance. (1) Anti-galling performance: According to the standard requirements, the threaded joints of oil and casing need to be tested for make-up and ma...Read more -

Characteristics of common industrial steel pipe piles

Steel pipe piles are widely used in various situations such as supporting piles and friction piles. Especially when used as supporting piles, because they can be fully driven into a harder supporting layer, they can play the bearing role of the entire cross-sectional strength of the steel. Even i...Read more -

Nondestructive testing of pipe fittings and flanges

Relevant provisions in the national standard for pipe fittings “GB/T13401-2017 Technical Specifications for Steel Butt-welded Pipe Fittings”: First, nondestructive testing 1. Tees, crosses, pressed reducers and pipe caps formed by direct cutting of bars of all material categories shal...Read more -

The difference between 304, 316L, and duplex stainless steel pipe fittings

Duplex stainless steel pipe fittings have the performance characteristics of both 304 and austenitic stainless steel pipe fittings. This article compares duplex stainless steel pipe fittings with stainless steel pipe fittings made of 304 and 316L as the main materials, and draws the following dif...Read more -

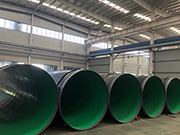

What are the functions of the structural components of 3PE anti-corrosion steel pipe

3PE anti-corrosion steel pipe is a relatively advanced anti-corrosion technology in recent years. Its full name is fused epoxy/extruded polyethylene structural protective layer. The structure of 3PE anti-corrosion steel pipe consists of the following three layers: the bottom layer is fused epoxy;...Read more -

What are the methods for surface treatment of the industrial steel pipes

Long-term exposure of steel and other metal materials to the atmosphere will inevitably lead to corrosion, forming loose rust, which will cause serious losses to modern industry. At present, pipelines play an important role in various industries, so the surface treatment of steel pipes is also on...Read more