-

Application field of spiral steel pipe for sewage discharge

Spiral pipe is made by rolling low-carbon carbon structural steel or low alloy structural steel strip into a tube blank according to a certain helical angle (called forming angle), and then welding the pipe seam. It can be made with a narrower strip Steel produces large diameter steel pipes. Its ...Read more -

Factors affecting the yield strength of seamless pipe

Yield strength is an important concept in the field of seamless pipe mechanics. It is the stress value of seamless steel pipe when the ductile material yields. When the seamless steel pipe will deform under the action of force, the deformation at this time can be divided into two ways: plastic de...Read more -

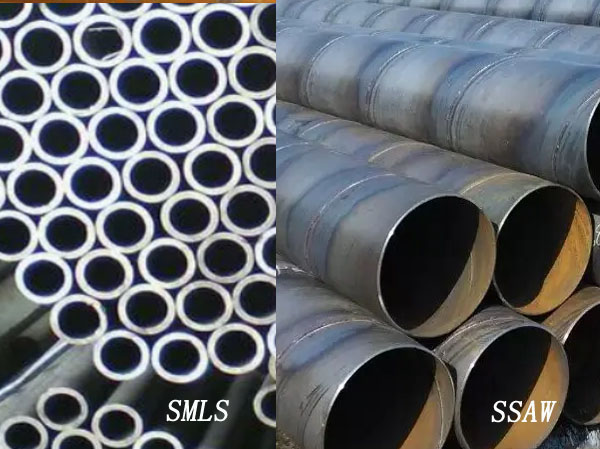

Differences between spiral steel pipe and seamless steel pipe

Spiral steel pipes and seamless steel pipes are relatively common pipes in life, and they are used in house decoration and construction. So what is the difference between spiral steel pipes and seamless steel pipes? What is a spiral steel pipe? Spiral steel pipe (SSAW) is a spiral seam steel pi...Read more -

Precautions for storage and transportation of large diameter spiral welded pipe

What are the precautions for storage and transportation of large-diameter spiral welded pipes? The following editor will introduce it to you. 1. Pipe packaging should be able to avoid loosening and damage during normal loading, unloading, transportation and storage. 2. If the buyer has spe...Read more -

Role of Welding Preheating

Preheating means a process that heat weldments in whole or in weld areas before welding. Particularly good material for welding high strength level, hardening tendency of steel, thermal conductivity, thickness larger weldments, and when the ambient temperature is too low,welding zone often requir...Read more -

Manufacture and application of seamless steel tube

Seamless tubes are tubes without seams or welds. Seamless steel tubes are considered to be able to withstand higher pressures, higher temperatures, higher mechanical stress and corrosive atmospheres. 1. Manufacturing Seamless steel tubes are manufactured using a number of different methods. The m...Read more -

The importance and advantages of anti-corrosion steel pipe

Anti-corrosion steel pipes play important and different roles in people’s daily life. Anti-corrosion steel pipes generally refer to the use of special processes to carry out anti-corrosion treatment on ordinary steel pipes (such as seamless pipes, welded pipes), so that the steel pipes have...Read more -

ERW pipe standard

ERW pipe standard are as follows: API 5L, ASTM A53 B, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672 API 5L Standard aims to gas and water in oil and gas industry for reference, which is used for seamless steel pipe and welded steel pipe,including common port and port, pipe socket port...Read more -

Principle of automatic butt welding machine for steel pipe

The preheating flash welding process: before the continuous flash welding is stopped, the welding machine is preheated to the reinforcing steel. Clamp the steel bar on the jaw of the butt welder. After the power is turned on, the open end is used to make the end face of the steel bar smash with l...Read more -

How to choose a high-quality seamless steel pipe manufacturer?

Most industries have relatively high requirements for seamless steel pipes, and steel pipes need to be purchased in batches during construction. Naturally, it is still necessary to measure the price and pay attention to the choice of manufacturers. So how to choose a high-quality seamless steel p...Read more -

Hot-expanded seamless steel pipe manufacturing process – cross rolling

Cross rolling is a rolling method between longitudinal rolling and cross rolling. The rolling of the rolled piece rotates along its own axis, deforms and advances between two or three rolls whose longitudinal axes intersect (or incline) in the same direction of rotation. Cross rolling is mainly u...Read more -

Cross-rolling piercing process and quality defects and their prevention

The cross-rolling piercing process is the most widely used in the production of seamless steel pipes, and was invented by the German Mannesmann brothers in 1883. The cross-rolling piercing machine includes two-roll cross-rolling piercing machine and three-roll cross-rolling piercing machine. The ...Read more