-

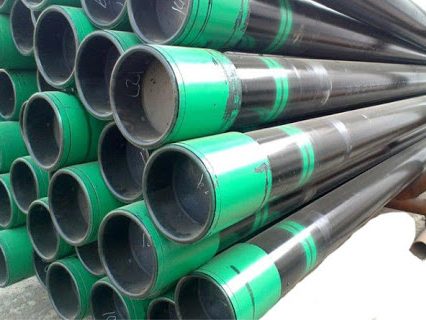

Anticorrosion method of petroleum casing

Anticorrosion method of petroleum casing The anticorrosion of oil casing is mainly divided into: 1. Brush anti-corrosion coating on the outer wall. 2. Brush anti-corrosive coating on the inner wall. 3. Brush the anti-corrosion cooling coating. With the use of oil casings in the harsh oil mining i...Read more -

Elbow

The elbow is a fitting that can change the direction of the pipe. You can see bends at intersections, turns, beams, etc. of pipes. The main forms of pipe elbows are: elbows of various angles, U-shaped pipes, round elbows (or B-shaped elbows) and curved elbows. According to different manufacturing...Read more -

What is the polishing effect of stainless steel pipe fittings?

The polished tube with bright surface is bright and clean and easy to clean. There is an invisible protective film that prevents the surface of the tube from being corroded and is not easily deposited. Life will be longer. The matte surface of the silk tube has the advantages of elegant appearanc...Read more -

Four advantages of anti-corrosion steel pipe in practical application

Four advantages of anti-corrosion steel pipe in practical application 1. The construction is simple and the steps are quick, and the construction can be carried out in the factory and on site. Compared with the old steel pipe, the construction of anti-corrosion steel pipe is very simple, does not...Read more -

SSAW Steel Pipe Price

API 5L/ASTM A53 GR.B, CARBON STEEL, SSAW STEEL PIPE FOB TIANJIN USD/TON Outside Diameter 外径 (mm) 219 273 324 356 406 457 508 610 711 762 813 914 Wall Thickness 6 544 544 544 544 544 544 544 544 549 549 549 549 壁厚 (mm) 7 544 544 544 544 544 544 544 544 549 549 549 549 8 544 ...Read more -

Seamless Steel Pipe Price

Read more -

LSAW Steel Pipe Price

API 5L GR.B/ASTM A53 GR.B, CARBON STEEL, LSAW STEEL PIPE FOB TIANJIN Outside Diameter 外径 (mm) USD/TON 406 457 508 609.6 711.1 762 812 863.6 Wall 8 676 669 676 663 668 663 668 668 Thickness 9.53 669 656 663 644 649 644 649 649 壁厚 (mm) 10 637 624 631 644 649 644 649 649 12...Read more -

Small Diameter ERW Steel Pipe Price

API 5L/ASTM A53 GR.B (Small Diameter ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 33.4 (1R...Read more -

Hot Rolled ERW Steel Pipe Price

API 5L/ASTM A53 GR.B (Hot Rolled ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 219、245 5.0-11...Read more -

Hot Expanded ERW Steel Pipe Price

API 5L GR.B/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 外径 (mm) 壁厚 (mm) (Q235B)离港价 USD/TON (Q345B)离港价 USD/TON 245, 2...Read more -

Practical significance of steel pipe process

(1) Enhance industrial manufacturing capabilities and save energy and resources. At present, the development trend of seamless steel pipe reduction technology is more product varieties and higher steel pipe quality, which is reflected not only in higher product dimensional accuracy but also in go...Read more -

Key points of new virus affecting steel industry

The steel industry is a basic industry with a large economic scale, long industrial chain, and many related industries. Even without this epidemic, operations will be affected by multiple factors such as macroeconomics, financial markets, raw materials, and terminal demand. The complexity of the ...Read more