-

Stages and standard parameters of the mechanical expansion process of large-diameter steel pipes

First, the stages of the mechanical expansion process of large-diameter steel pipes: The steel plate is first pressed into a U shape in the forming die, then pressed into an O shape, and then internal and external submerged arc welding is performed. After welding, the diameter is usually expanded...Read more -

Implementation standards and technological progress of straight seam steel pipes

Welded steel pipes, also known as welded pipes, are steel pipes made by welding steel plates or steel strips after curling and forming. The production process of welded steel pipes is simple, the production efficiency is high, the varieties and specifications are many, and the equipment investmen...Read more -

The main reasons for the decline in the quality of steel pipe bending pipe

Analysis of the main reasons for the decline in the quality of steel bending pipe and precautions. During pure bending, the outer arm wall of the neutral layer of the steel pipe is thinned by the tensile stress &1 under the action of the external force M, and the inner side is subjected to co...Read more -

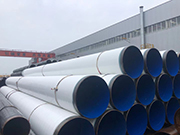

Composition and production process of epoxy resin anti-corrosion steel pipe

First, the composition of epoxy resin anti-corrosion steel pipe 1. Steel pipe: seamless steel pipe, straight seam steel pipe, spiral steel pipe and other steel pipes 2. Epoxy resin coating This product is a two-component, high-solid coating with epoxy resin as the main agent. It is divided into p...Read more -

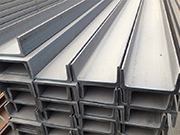

The main uses and characteristics of steel structures in common industrial projects

First, the characteristics of steel structures 1. Steel structures are light in weight and high in bearing capacity: they are lightweight and high-strength materials 2. Steel is close to a homogeneous isotropic body: when steel is divided into tiny pieces, each piece will have roughly the same me...Read more -

How to choose welding methods when welding steel pipes

The commonly used welding methods in steel pipe welding, installation, and construction in the petroleum, chemical, natural gas, shipbuilding, and other industries are mainly the following: ① SMAW, due to its slow welding speed and the welding quality being greatly affected by the operator, its a...Read more -

Precautions for quality inspection of steel pipe welds

Welding quality inspection refers to: using methods such as investigation, inspection, measurement, testing, and detection to compare welding quality with the use requirements of welded steel pipes, prevent continuous production of unqualified steel pipes, and avoid the occurrence of quality acci...Read more -

Why do some stainless steel pipes need degreasing

We all know that stainless steel pipes need to be pickled and passivated before leaving the factory. However, sometimes users ask for re-degreasing of the pipes? For pipes, the more reasonable degreasing should be completed on-site, that is, after all the pipes are installed, the degreasing shoul...Read more -

Characteristics and Application of the External Galvanized Steel Pipes

Steel pipes, as an indispensable material in the construction industry and engineering field, play an important role. Among them, external galvanized steel pipes, as a common and widely used steel pipe variety, have unique characteristics and a wide range of applications. 1. Definition of externa...Read more -

Differences and application areas between carbon steel pipe and seamless steel pipe

Carbon steel pipe and seamless steel pipe are two common pipes in the steel industry. There are some differences between them in manufacturing process and performance characteristics. 1. Definition and manufacturing process Carbon steel pipe is a steel pipe with carbon element as the main alloyin...Read more -

Causes and solutions for spots on stainless steel pipes after cleaning

In the steel industry, stainless steel pipes are favored for their excellent corrosion resistance and beautiful surface quality. However, during use, spots are sometimes found on the surface of stainless steel pipes. This not only affects the beauty of stainless steel pipes but may also have a ce...Read more -

The manufacturing process and application field of 1.6MPa hot-dip galvanized steel pipe

Hot-dip galvanized steel pipe is a common and important building material, which is widely used in all walks of life. Among them, 1.6MPa hot-dip galvanized steel pipe, as a special specification, has a unique position in the engineering field. 1. Hot-dip galvanized steel pipe manufacturing proces...Read more