-

Difference between pipeline welding and TIG welding backing

Full TIG welding backing makes no difference in the process, the whole arc for thin-walled small diameter pipes (DN50 general and below, the wall thickness of 4 mm) or less, the purpose of guarantee good weld root quality appearance imaging. When a large diameter, thick wall thickness should be u...Read more -

Degaussing pipes

Residual magnetism causes and impact on quality of welding in the construction and repair of gas pipelines welding job, sometimes magnetic blow phenomena affect the welding process. Forming a magnetic blow is the result of the presence of residual magnetism of the tube metal. Typically, magnetic ...Read more -

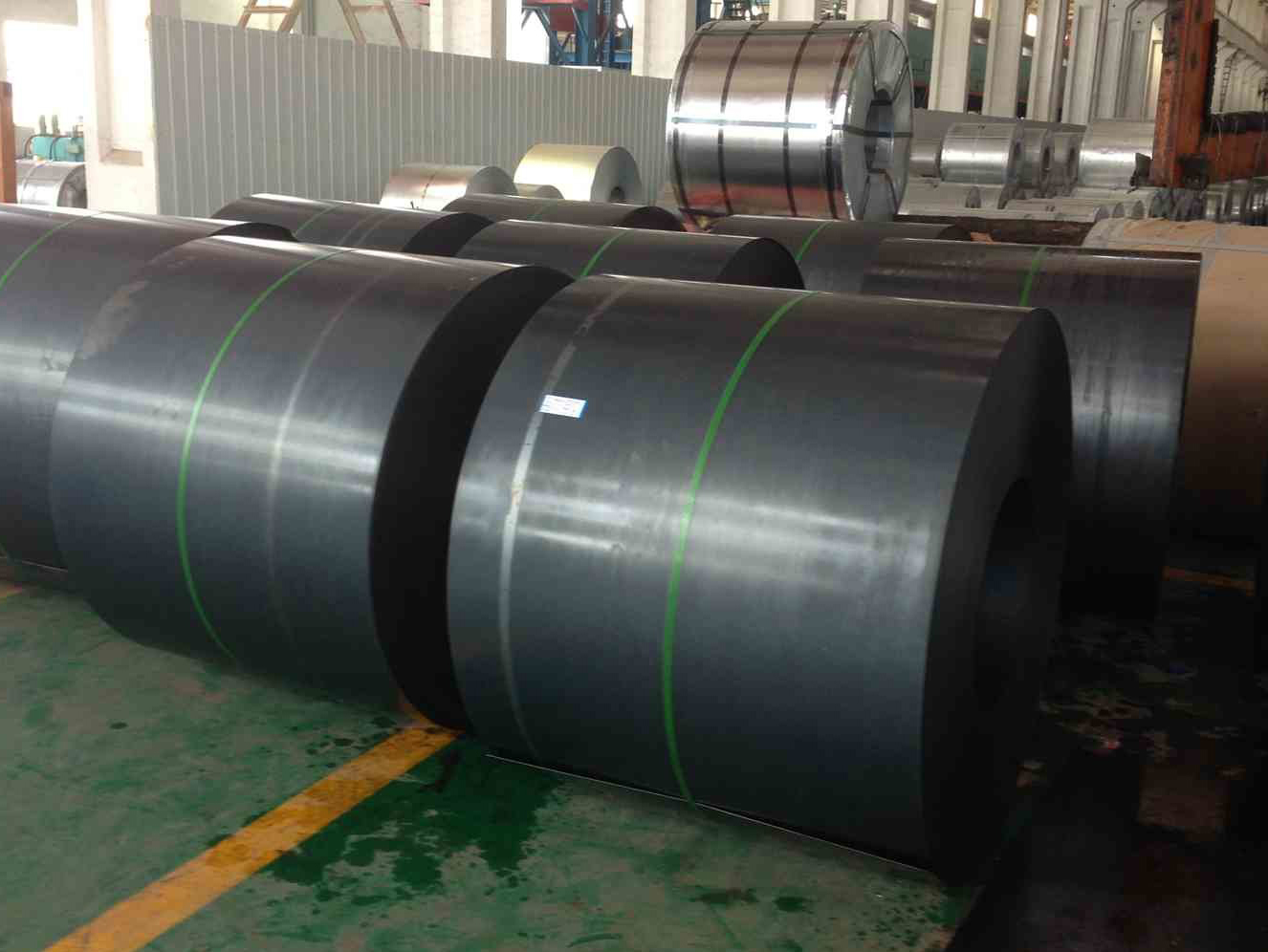

Continuous annealing

Continuous annealing is a relative terms batch annealing, continuous annealing of the strip through a continuous annealing furnace, annealing furnace without sealing strip without staying directly coiling of production. In production applications, the continuous annealing wide application, contin...Read more -

Disadvantage and defect of resistance welding

Resistance welding is pressed welders parts between the two electrodes, and go through to the current use of resistance heat generated by current flowing through contact with the workpiece surface and the neighboring regions to be heated to the melting or plastic state, so as to form metal-bindin...Read more -

Disadvantages of steel pickling process

Pickling is widely used in hot-rolled sheet metal blank that the removal of surface oxide scale, such as hot-rolled steel pipe in need of phosphate or other surface coating before processing to remove iron oxide; welded pipes in galvanized or other hot-dip galvanizing, plating surface preparation...Read more -

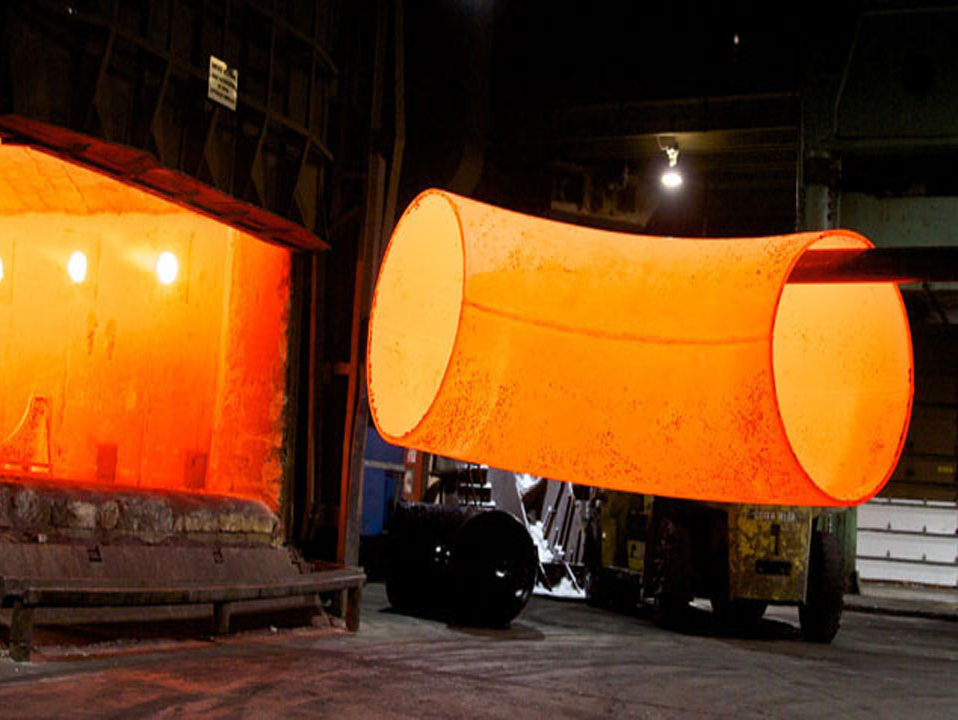

Heat treatment process for steel pipe

The quality of heat treatment is directly related to subsequent processing quality and eventually affect the performance and life of the parts, heat treatment is the energy consumption of the machinery industry big polluters. In recent years, with the advancement of science and technology and its...Read more -

Analysis of welded pipe pressure burst

Delivery with steel pipes have been more and more widely used in various industries, and steel pipe multi-buried in damp underground, which has strict requirements for the use of performance of the steel pipe. Existing heat transmission with welded pipe leak in use, check the steel pipe partial s...Read more -

Eddy current testing(ET)

Eddy current testing(ET) use the principle of electromagnetic induction to detect a flaw detection method of the conductive member surface and near-surface defects. Its principle is based on the excitation coil so that the conductive member generates eddy currents, by means of determination of th...Read more -

Galvanized coating on pipe surface

Galvanized coating has a number of characteristics that make it a well-suited corrosion protective coating for iron and steel products in most environments. Th excellent field performance of Galvanized coating results from its ability to form dense, adherent corrosion product films of corrosion c...Read more -

High frequency pipe manufacturing control

1.The pipe weld gap control Adjust the amount of squeezing rollers squeeze, so keep the flush weld ends, the opening angle of 7 degrees or less, the weld gap control between 1-3 mm. Weld control is too large, it may appear bad, weld cracking to produce incomplete fusion or weld control is too sma...Read more -

Comparison of high frequency induction welding with high-frequency resistance welding

High-frequency resistance welding basic principle: a pair of electrodes two leg edge contact with the tube, directly to the edge of the input frequency current tube, using high frequency current of the skin effect and proximity effect, so that the current is highly concentrated in the edge of the...Read more -

Application of Protection coating for reinforced concrete

Changes of concrete alkaline state would destroy the steel surface of the passive film, then there reinforcement the localized corrosion. Corrosion of reinforcement is reinforced concrete structure damage and one of the main causes of early failure. With domestic steel corrosion in concrete struc...Read more