-

Learn more about the performance, application, and purchase guide of seamless 478 steel pipes

Seamless 478 steel pipes are an important pipe material in the steel industry, with a wide range of applications and excellent performance. 1. Performance characteristics of seamless 478 steel pipes: - High strength: Seamless 478 steel pipes have high strength, can withstand greater pressure and ...Read more -

Q235C seamless hot-rolled steel pipe is the application of high-quality materials in engineering project

Q235C seamless hot-rolled steel pipe is a common steel pipe product with good plasticity and weldability and is widely used in various fields. First, Q235C seamless hot-rolled steel pipe has the following characteristics: 1. High-quality material: Q235C is a kind of carbon structural steel with g...Read more -

Importance of Carbon Steel Pipe Diameter Standards

In the steel industry, carbon steel pipe is a common material with a wide range of uses, and the diameter standards of carbon steel pipes are of great significance for engineering design and use. Carbon steel pipe diameter standards refer to the specified range of pipe diameters, usually expresse...Read more -

Production process and advantages of hot-dip galvanized steel pipes

First, the production process of hot-dip galvanized steel pipes Hot-dip galvanized steel pipes, also known as hot-dip galvanized pipes, are steel pipes that are galvanized to improve their performance. The principle of its processing and production is to react molten metal with the iron matrix to...Read more -

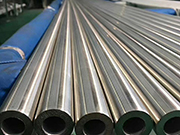

Common industrial stainless steel welded pipe implementation standards and production process

First, what are the implementation standards for stainless steel welded pipes? There are multiple standards for stainless steel welded pipes. The following are some of the main implementation standards: 1. GB/T 12771-2024: This is the latest implementation standard for stainless steel welded pipe...Read more -

Industrial stainless steel pipe selection guide

First, what materials are available on the market, and what are the differences in quality? Currently, there are mainly 304, 201, and 301 materials on the market. The difference is mainly caused by the different contents of chromium and nickel. Material 304 contains 18 chromium and 8-9 nickel, wh...Read more -

304 chemical stainless steel pipeline is a corrosion-resistant industrial artery

In the context of modern industry, 304 chemical stainless steel pipelines are like tough arteries, carrying the flow of chemicals and maintaining the lifeline of production. This pipeline has become an indispensable partner in the chemical, petroleum, food processing, and other industries with it...Read more -

Explore the advantages and application prospects of 2535 steel pipes

2535 steel pipe, as a special steel pipe material, plays an important role in the industrial field. In today’s steel industry, 2535 steel pipes have attracted much attention due to their unique properties. This type of steel pipe is mainly composed of chromium, nickel, copper, molybdenum, a...Read more -

Explore the excellence of DN800 steel pipe

In modern construction and infrastructure construction, steel pipe is a vital material. Among them, DN800 steel pipe has attracted much attention and has become the darling of the engineering field because of its unique characteristics. Let us take a deeper look at this outstanding building mater...Read more -

Structural stainless steel tubing is the choice for light and strong construction

Structural stainless steel pipes are a common and important building material. They are widely used in bridges, building structures, interior decoration, and other fields. In construction projects, structural stainless steel pipes, with their unique properties, give buildings lightness and solidi...Read more -

Analysis of the causes of transverse cracks on the inner wall of cold-drawn seamless steel pipes

1. Analysis of crack characteristics It can be seen that there are many transverse cracks distributed along the longitudinal direction of the steel pipe. The cracks are arranged neatly. Each crack has a wavy feature, with a slight deflection in the longitudinal direction and no longitudinal scrat...Read more -

Quenching deformation in steel pipe production

1. Residual stress and deformation: When steel is heated to about 450℃, it changes from an elastic body to a plastic body, and plastic deformation is likely to occur at this time. On the other hand, when heated to about above 450℃, the stress disappears due to the residual recrystallization. Ther...Read more