-

10 Ways to remove burrs from seamless steel tubes

Burs are ubiquitous in the metalworking process. No matter how advanced and sophisticated equipment you use, it will be born with the product. This is mainly due to the plastic deformation of the material and the generation of excessive iron filings at the edges of the processed material, especia...Read more -

Stress of API 5CT Oil Casing in Oil Well

The stress on the API 5CT oil casing in the oil well: to ensure that the casing running into the well is continuous, not cracked or deformed, the casing is required to have a certain strength, enough to resist the external force it receives. Therefore, it is necessary to analyze the stress on the...Read more -

Six processing methods commonly used for seamless pipes

There are six main processing methods for seamless pipes (SMLS): 1. Forging method: Use a swage forging machine to stretch the end or part of the pipe to reduce the outer diameter. Commonly used swage forging machines include rotary type, connecting rod type, and roller type. 2. Stamping method: ...Read more -

Tensile strength and influencing factors of seamless pipe

Tensile strength of seamless pipe (SMLS): Tensile strength refers to the maximum tensile stress that a material can withstand when it is stretched by an external force, and it is usually used to measure the damage resistance of a material. When a material reaches tensile strength during stress, i...Read more -

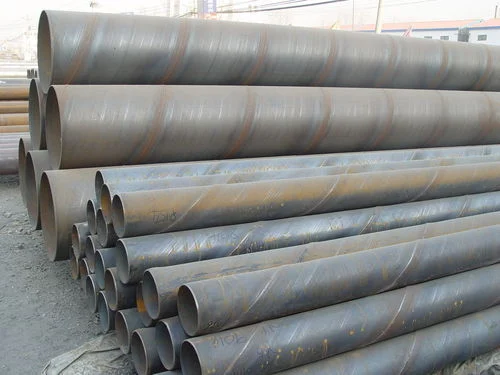

Advantages, disadvantages and development direction of spiral welded pipe

Spiral welded pipe (ssaw): It is made by rolling low-carbon carbon structural steel or low alloy structural steel strip into a tube blank according to a certain helical angle (called forming angle), and then welding the pipe seam. It can be made with narrower strip steel produces large diameter s...Read more -

General regulations for carbon steel pipe installation

The installation of carbon steel pipes should generally meet the following conditions: 1. The pipeline-related civil engineering experience is qualified and meets the installation requirements; 2. Use mechanical alignment to connect with the pipeline and fix it; 3. Relevant processes that must b...Read more -

Manufacturing principle and application of seamless pipe

Manufacturing principle and application of seamless pipe (SMLS): 1. The production principle of seamless pipe The production principle of the seamless pipe is to process the steel billet into a tubular shape under the conditions of high temperature and high pressure, so as to obtain a seamless pi...Read more -

Matters needing attention when purchasing carbon steel tubes

With the continuous advancement of the global industrialization process, the demand for carbon steel tubes (cs tube) is increasing year by year. As a commonly used piping material, carbon steel tubes are widely used in many fields such as energy, construction, and chemical industry. However, when...Read more -

Main quality testing items and methods of seamless pipes

The main quality testing items and methods of seamless pipes: 1. Check the size and shape of the steel pipe (1) Steel pipe wall thickness inspection: micrometer, ultrasonic thickness gauge, no less than 8 points at both ends and record. (2) Steel pipe outer diameter and ovality inspection: callip...Read more -

What are the steel pipe products around you?

Steel pipe products are indispensable and important products in today’s society, and they are widely used in various industries. 1. Qualification of steel pipe products The qualification of steel pipe products refers to whether the quality of steel pipe products meets the standards stipulat...Read more -

Carbon steel tube flaw detection method

Commonly used non-destructive testing methods for carbon steel tubes are: ultrasonic testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT) and X-ray testing (RT). The applicability and limitations of ultrasonic testing are: It mainly uses the strong penetrability and good di...Read more -

How to choose spiral pipe or seamless pipe?

When it comes to steel pipe selection, there are usually two options: spiral pipe and seamless pipe. While both have their own advantages, spiral steel pipe is usually more economical in terms of price. The production process of spiral steel pipe is relatively simple, mainly including forming, we...Read more