-

API 5L/ASTM A53 GR.B (HOT ROLLED ERW STEEL PIPE) PRICE LIST

API 5L/ASTM A53 GR.B (Hot Rolled ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) 离港价 USD/TON 外径 (mm) 壁厚 (mm) 离港价 USD/TON 219、245 5.0-11.75 586.76 426 5.75-11.75 593.68 273 5.0-11.75 586.76 12....Read more -

API 5L/ASTM A53 GR.B, CARBON STEEL, SSAW STEEL PIPE PRICE LIST

API 5L/ASTM A53 GR.B, CARBON STEEL, SSAW STEEL PIPE FOB TIANJIN USD/TON Outside Diameter (mm) 219 273 324 356 406 457 508 610 711 762 813 914 Wall Thickness (mm) 6 620 620 620 620 620 620 620 620 620 620 620 620 7 620 620 620 620 620 620 620 620 620 620 620 620 ...Read more -

API 5L/ASTM A106 GR.B, SEAMLESS CARBON STEEL PIPE PRICE LIST

API 5L/ASTM A106 GR.B, Seamless Carbon Steel Pipe 公称通径 DN 外径OD (mm) SCH40(6m/5.8m) SCH80(6m/5.8m) SCH160(6m/5.8m) 壁厚WT FOB 壁厚WT FOB 壁厚WT FOB (mm) USD/TON (mm) USD/TON (mm) USD/TON 1/4” 13.7 2.24 1,117.27 3.02 1,117.27 / / 3/8” 17.1 2.31 978.95 3.2 978.95 / / 1/2” 2...Read more -

API 5L/ASTM A53 GR.B, CARBON STEEL, LSAW STEEL PIPE PRICE LIST

API 5L/ASTM A53 GR.B, CARBON STEEL, LSAW STEEL PIPE Outside Diameter (mm) FOB TIANJIN USD/TON 406 457 508 609.6 711.1 762 812 863.6 Wall 8 750 743 750 736 736 736 736 736 Thickness 9.53 743 729 736 715 715 715 715 715 (mm) 10 708 695 702 715 715 715 715 71...Read more -

API 5L/ASTM A53 GR.B (SMALL DIAMETER ERW STEEL PIPE) PRICE LIST

API 5L/ASTM A53 GR.B (Small Diameter ERW Steel Pipe) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) 离港价 USD/TON 外径 (mm) 壁厚 (mm) 离港价 USD/TON 33.4 (1″) 2.1-2.4 603.06 Φ133 3.0-5.75 579.44 2.5-3.25 583.61 ...Read more -

API 5L/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE) PRICE LIST

API 5L/ASTM A53 GR.B (HOT EXPANDED ERW STEEL PIPE) Outside Diameter Wall Thickness FOB TIANJIN Outside Diameter Wall Thickness FOB TIANJIN 外径 (mm) 壁厚 (mm) 离港价 USD/TON 外径 (mm) 壁厚 (mm) 离港价 USD/TON 245, 273 5.0-9.28 592.96 450, 457, 508, 530 6.5-11.98 627.53 9.45-9.98 ...Read more -

Explore the manufacturing process and application of 310S large-diameter stainless steel pipes

Large-diameter stainless steel pipes play an important role in modern industry, and 310S stainless steel pipes are one of them. 1. Characteristics of 310S large-diameter stainless steel pipes 310S stainless steel pipes are a high-temperature and corrosion-resistant stainless steel pipe material w...Read more -

What should be paid attention to when welding steel pipes

1. Cleaning of steel pipes. Note that before welding steel pipes, cleaning work must be done first. The surface of the steel pipe may have various oils, paints, water, rust, etc., and may also be mixed with various impurities. To ensure the smooth progress of welding and reduce safety issues, it ...Read more -

Explanation of the advantages of fire-fighting plastic-coated steel pipes over galvanized steel pipes

Explanation of the advantages of fire-fighting plastic-coated steel pipes over galvanized steel pipes, the difference between galvanized steel pipes and plastic-coated steel pipes, with the continuous decline of steel billet quotations, the market quotation is also falling day by day, and because...Read more -

How to do the safety management of spiral steel pipes

To solve the problem of excessive misalignment in the alignment of spiral steel pipe nozzles, the following preventive measures should be taken in quality management control: 1. Try to use the internal alignment device. 2. Do a good job of engineering measurement and trimming during assembly. 3. ...Read more -

904L stainless steel pipe is a magical material with super corrosion resistance

904L stainless steel pipe is a highly anticipated material with super corrosion resistance and is widely used in chemical, petroleum, pharmaceutical, and other fields. 1. Characteristics of 904L stainless steel pipe 904L stainless steel pipe is a special stainless steel material with the followin...Read more -

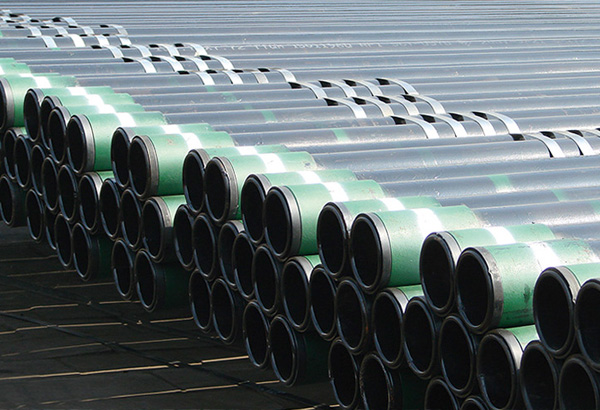

API 5CT CASING STOCK FOR SALE

For Immediate Sale In order to give back to our customers, we sold some of our stock pipes at a very competitive price, all the following pipe are new with high quality, and it can be ready for for immediate delivery. 1 - Packing : With safety package. 2 – All pipes are be inspec...Read more