-

Galvanized pipe pretreatment

Process: degreasing → flow cleaning → conditioning → phosphating → washing → drying. Non galvanized pipe process Degreasing rust → washing → neutralization flow → conditioning → phosphating → washing → drying. First, the oil pool management In strict accordance with the ratio of 1:20, that is 1 k...Read more -

Heat preservation method of making the spiral steel pipe

Spiral pipe insulation pipe methods wherein a process starting from the pipe wall as inhibition plus anti-corrosion coating, loop resistance can be increased, reducing the corrosion current;. External DC power supply, the steel pipe to soil caused negative potential to form a cathode protection, ...Read more -

ERW pipe weld joint

The most important feature is that no foreign ERW weld filler metal, heating speed, high production efficiency. This is its advantages, but also its shortcomings. No filler metal, the filler alloy can not benefit approach elements improve weld properties; heating temperature is high, when the sou...Read more -

Difference between pipeline welding and TIG welding backing

Full TIG welding backing makes no difference in the process, the whole arc for thin-walled small diameter pipes (DN50 general and below, the wall thickness of 4 mm) or less, the purpose of guarantee good weld root quality appearance imaging. When a large diameter, thick wall thickness should be u...Read more -

Degaussing pipes

Residual magnetism causes and impact on quality of welding in the construction and repair of gas pipelines welding job, sometimes magnetic blow phenomena affect the welding process. Forming a magnetic blow is the result of the presence of residual magnetism of the tube metal. Typically, magnetic ...Read more -

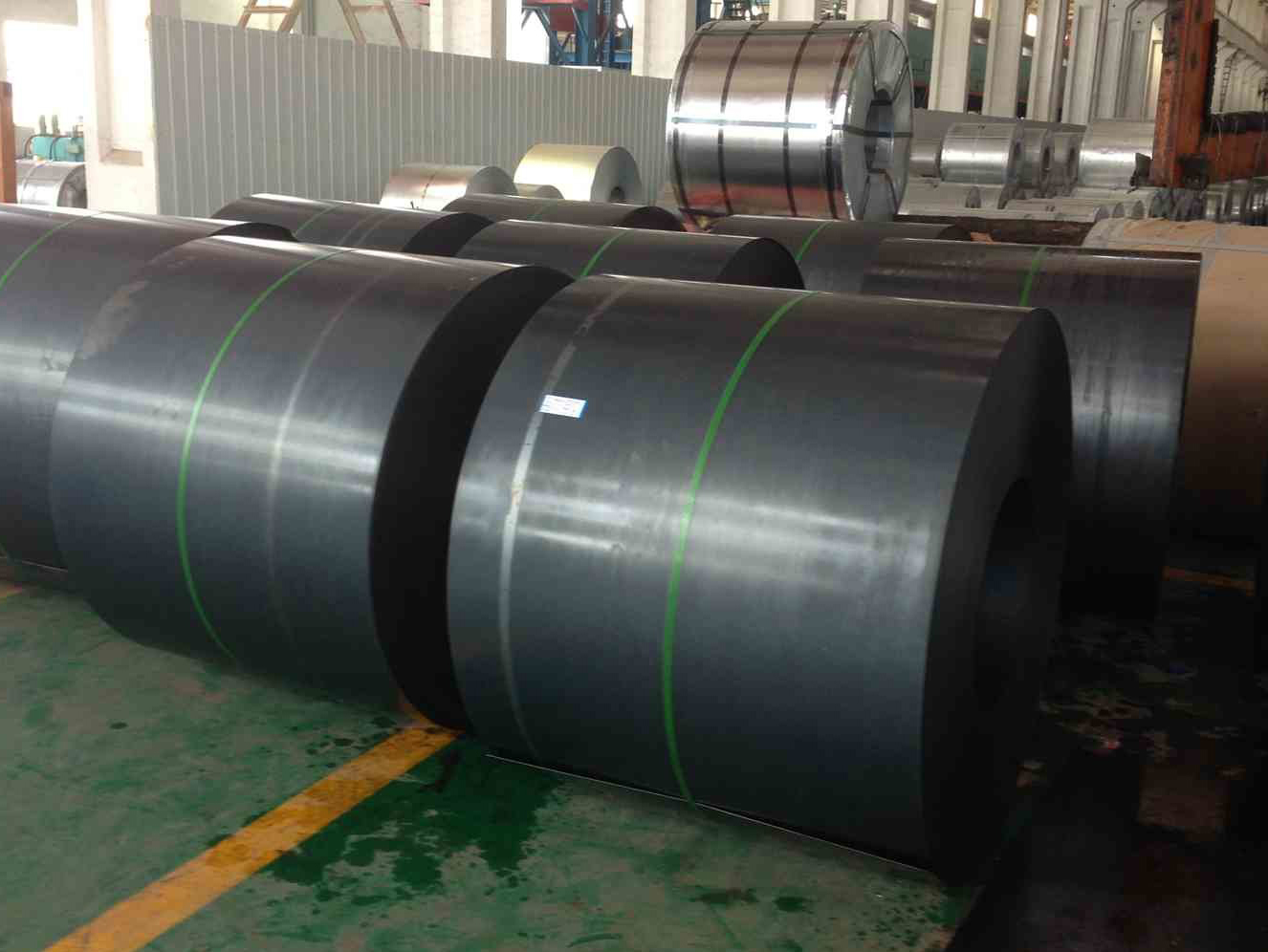

Continuous annealing

Continuous annealing is a relative terms batch annealing, continuous annealing of the strip through a continuous annealing furnace, annealing furnace without sealing strip without staying directly coiling of production. In production applications, the continuous annealing wide application, contin...Read more -

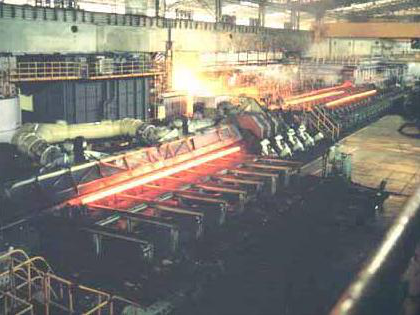

Hot rolled seamless steel pipe

Hot-rolled seamless steel pipe: hot rolled is relative to the cold-rolled, cold rolling is below the recrystallization temperature of the rolling, and hot rolled is carried out at above the recrystallization temperature of the rolling. Advantages: hot rollded seamless steel pipe can damage the ca...Read more -

High-pressure boiler tube heat defect

High-pressure boiler tubes are frequently occurs fault because of high temperatures, affecting the entire heating system, mainly due to an internal boiler for heat treatment is not perfect, a lot of heat can not be effectively converted and timely treatment. Burnt phenomenon Generally refers to t...Read more -

ERW oil casing application and market analysis

In the field of oil drilling and oil well, high-frequency electric resistance welded casing (referred to as ERW casing) compared with seamless casing is high dimensional accuracy, weld toughness, anti-extrusion of high-performance, and low cost advantages, which has been widely used in foreign co...Read more -

Difference between Seamless and ERW Stainless steel pipe

What is the Raw material required for manufacturing Seamless & ERW Stainless steel Pipes? Seamless Steel Pipe is made from a solid round steel ‘billet’ which is heated and pushed or pulled over a form until the steel is shaped into a hollow tube. Billets are procured both from indigenous supp...Read more -

Common Welded Steel Pipes

As is known to all, there are many kinds of different welded steel pipes in the world. The welded steel pipes can be divided into many types according to its different material properties, technology of manufacturing and practical uses. In our daily life, the most commonly used welded steel pipes...Read more -

Large diameter spiral pipe submerged arc welding process

Welding way of spiral pipe is submerged arc welding; molding process, before tilting intermittent production; unit speed, 0.5–3m / min; welding speed, 0.5–3m / min. Units from uncoiling machine, straightening machine, on the device, hydraulic shears, milling welder, disc cutter, milli...Read more