-

Create a New Business Card of “Wisdom Made in China”

The “super fishing grounds” of China’s 12-stage typhoon have been delivered to Norwegian users. The “super fishing grounds” installed more than 20000 various types of sensors, integrated into the biology, engineering, electrical, computer and other multidisciplinary...Read more -

Carbon Steel-Heat Treatment

The purpose of heat treating carbon steel is to change the mechanical properties of steel, usually ductility, hardness, yield strength, or impact resistance. Note that the electrical and thermal conductivity are only slightly altered. As with most strengthening techniques for steel, Young’...Read more -

Galvanized pipe

Galvanized pipe manufaturing process Galvanized pipe sulfate electro-galvanized the ferroalloy process is the production trough perforation direct solution to bring out or overflow. Various production process from the circulatory system, the slot solution, alkali solution, plating solution, a lig...Read more -

Extruded steel pipe

Extruded steel pipe is produced by cold extrusion, hot extrusion, warm extrusion process. Hot extrusion is widely used in the production of aluminum, copper and other nonferrous metal pipes and profiles. Hot extrusion of steel for the production of both special pipes and profiles, it is difficult...Read more -

Do You Know How to Paint Carbon Steel Pipes?

Carbon steel pipes consist of an iron and carbon alloy that is able to be bent into shapes during manufacture without reducing its high tensile strength. So as black steel pipe, many people use black steel pipe now. It is vital to defend the metal surface location from corrosion credited to the m...Read more -

The difference between the steel tubes

Difference between ssaw steel pipe and lsaw steel pipe Metallurgical properties of raw materials Straight seam submerged arc welding tube is made of steel, but spiral submerged arc welding steel pipe production is usd hot rolled steel coil strip. The hot strip rolling process with a series of adv...Read more -

Deviation wall thickness of seamless steel pipe

In recent years, the proportion of seamless steel pipe in China’s steel production is growing, including seamless steel pipe wall thickness deviation is the importance of the quality one of the indicators due to its wide use and the higher its quality requirements. The thickness deviation d...Read more -

Large-diameter oil pipeline stress corrosion causes and preventive measures

Stress corrosion Cause Large diameter oil pipeline stress corrosion cracking is a lag time-related damage, this hydrogen delayed cracking completely similar. Stress corrosion cracking (SCC) is a low-stress brittle fracture. Q345B spiral steel stress corrosion can occur only in specific circumstan...Read more -

International Tender for ERW steel pipe

SUB: - International Tender for group; (A) ERW Line pipe 10’’ -24’’, GROUP- (B) ERWLINE PIPE 2’’-8’’, GROUP (F) Seamless line pipe 1’’-16’’ SUNDARBAN GAS COLTD, Khulna, will purchase ERW LINE PIPE & SEAMLESS LINE PIPE THROUGH International tender. Sunderban gas co ltd wants to make sure that ...Read more -

Hot dip process

Hot dip process Workpiece → degreasing → washing → pickling → washing → dip test help plated solvent → drying Preheat galvanized → finishing → hot dip → cooling → rinsing → drying →inspection Hot-dip galvanizing layer formation process Hot-dip galvanizing layer formation process is a proce...Read more -

High strength structural steel plate of cold forming performance

Inadequacies of high-strength steel structure is thermoformed and post-weld heat treatment temperature determination are limited material softening problem. Therefore, in practical applications in order to avoid affecting the thermoforming process on the mechanical properties of the material, the...Read more -

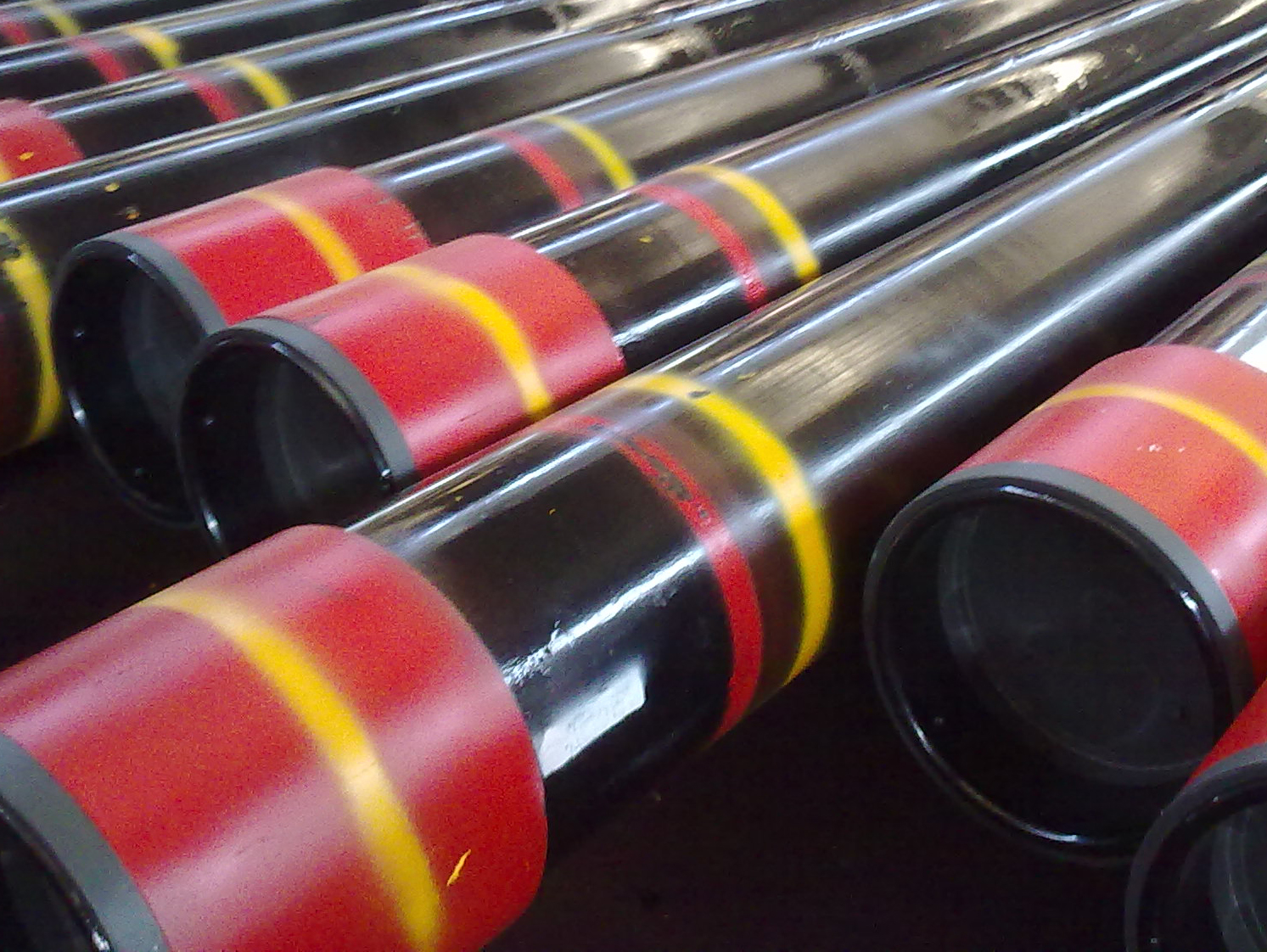

Casing tube

Heat treatment technology of oil casing Oil casing is a pipeline used for transportation oil or other raw materials, which has a good performance in use, users get the praise and love. Heating of the oil casing need to follow a certain temperature production, use of different temperature control ...Read more